GPP5010N-21-A

2-Jaw Parallel Grippers

Series GPP5000

"The best"

- Steel Linear Guide –

The superior guidance system concept

The steel / steel guide stands for lasting precision, durability and a long service life—featuring maintenance intervals of up to 30 million gripping cycles. Benefit from these features and increase the profitability and process reliability of your machine. - Leakproof and corrosion protected – The universal gripper

Suitable for virtually all ambient conditions, with a sealed guide up to IP67 and corrosion protection as standard, you are able to use this gripper universally. As a result, the range of models in your production is reduced, along with a reduction in associated storage and process costs.

Equipment/Options

30 million maintenance-free cycles (max.)

30 million maintenance-free cycles (max.) IP67

IP67 Protected against corrosion

Protected against corrosion Magnetic field sensor

Magnetic field sensor Inductive sensor

Inductive sensor Purged air

Purged air Steel Linear Guide

Steel Linear Guide

Technical Data

| Stroke per jaw | 10 [mm] |

| Gripping force in closing | 885 [N] |

| Gripping force in opening | 945 [N] |

| Closing time | 0.06 [s] |

| Opening time | 0.06 [s] |

| Dead weight of mounted gripper finger max. | 1.3 [kg] |

| Length of the gripper fingers max. | 160 [mm] |

| Repetition accuracy +/- | 0.01 [mm] |

| Operating pressure min. | 3 [bar] |

| Operating pressure max. | 8 [bar] |

| Nominal operating pressure | 6 [bar] |

| Operating temperature | -10 ... +90 [°C] |

| Air volume per cycle | 44 [cm³] |

| Clean room applications according to DIN EN ISO 14644-1 | 5 |

| Protection to IEC 60529 | IP67 |

| Protected against corrosion | Yes |

| Weight | 1.1 [kg] |

Accessory

Benefits in detail

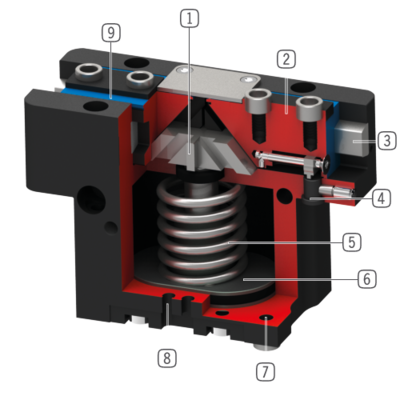

- Wedge hook mechanism

Supports to absorb high forces and moments Synchronized gripper jaw movement - Gripper jaw

Gripper fingers mounted using removable centering sleeves Lubricated for life via incorporated lubrication slots - Steel Linear Guide

Steel in steel guide Enables use of extremely long gripper fingers Also available in steel / aluminum variant - Mounting block

mounting for inductive proximity switch - Integrated gripping force safety device

Spring built into cylinder chamber as an energy store - Drive

Double-acting pneumatic rotor cylinder - Mounting and positioning

Alternatively, on several sides for customized mounting Pneumatic and electrical versions identical apart from height - Sensing slot

mounting and positioning of magnetic field sensors - Dual lip seal

IP64 and up to IP67 (with purged air) for Protector version Prevents grease from being squeezed out, increasing service life

Certificates clean room suitability

SERIES GPP5000 00-VERSIONS*

SERIES GPP5000 21-VERSIONS*

SERIES GPP5000 AL-VERSIONS*

*Certifications are valid for all versions only up to installation size GPP5016