ROBOT APPLICATIONS

The application areas of robots and cobots (collaborative industrial robots) are as versatile as they are essential for the automation of processes. In the industrial world, it is already common for machines and robots to handle tasks that are repetitive, monotonous, physically difficult or even dangerous. It is hard to imagine the production processes of today, such as those in the automotive, pharmaceutical and food industries, without robot applications. For a long time now, robots have been independently handling work processes and collaborating hand-in-hand with people. This not only makes the work environment safer, for example when hazardous substances are handled, but also makes it more cost-effective. So far, this has resulted in major potential savings for production costs, particularly in the case of manufacturing large quantities.

At the same time, the range of services and the demands made on state-of-the-art systems are becoming more and more extensive. Support for complex assembly tasks, transportation of heavy loads and monitoring production processes –the tasks are becoming more complex and the technological progress of hardware and software keeps advancing. Thanks to innovative software that makes commissioning and controlling decidedly easier and more convenient, the application areas of cobots and robots are also increasing considerably for the production of low quantities far from standardized mass production.

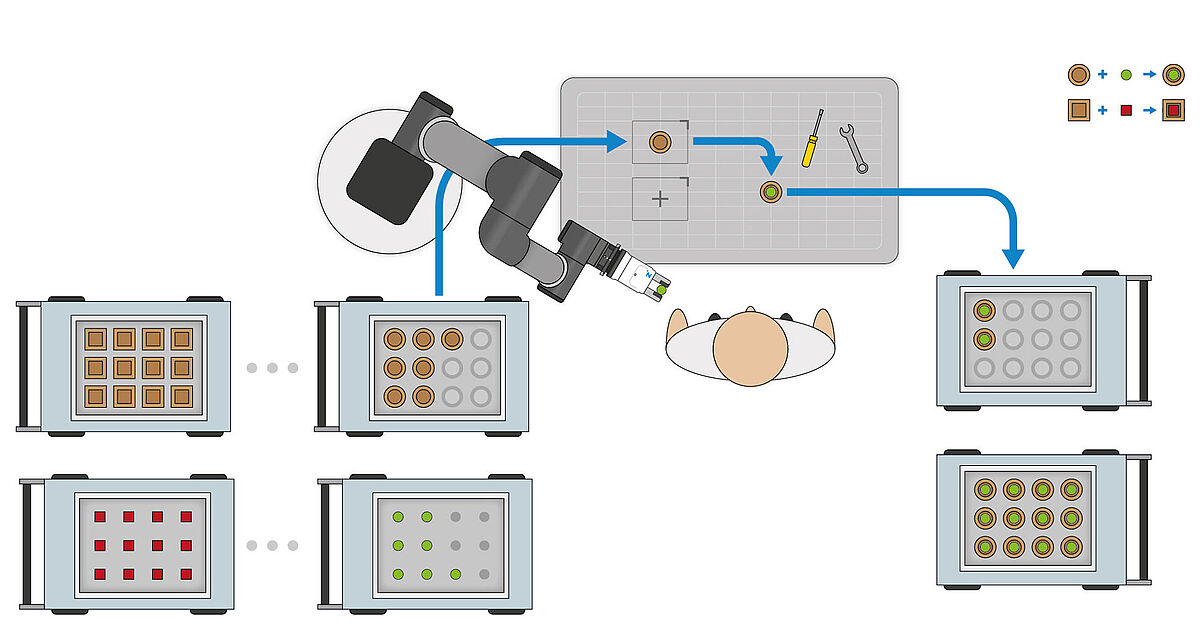

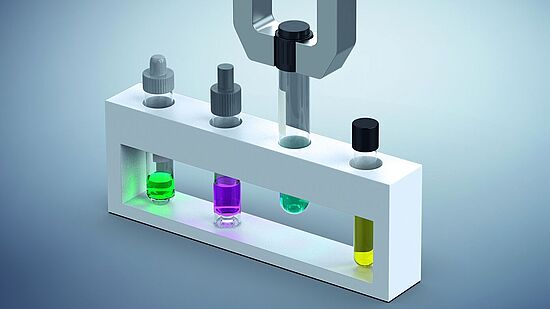

EXAMPLE 1: AUTOMATATED PICK-AND-PLACE

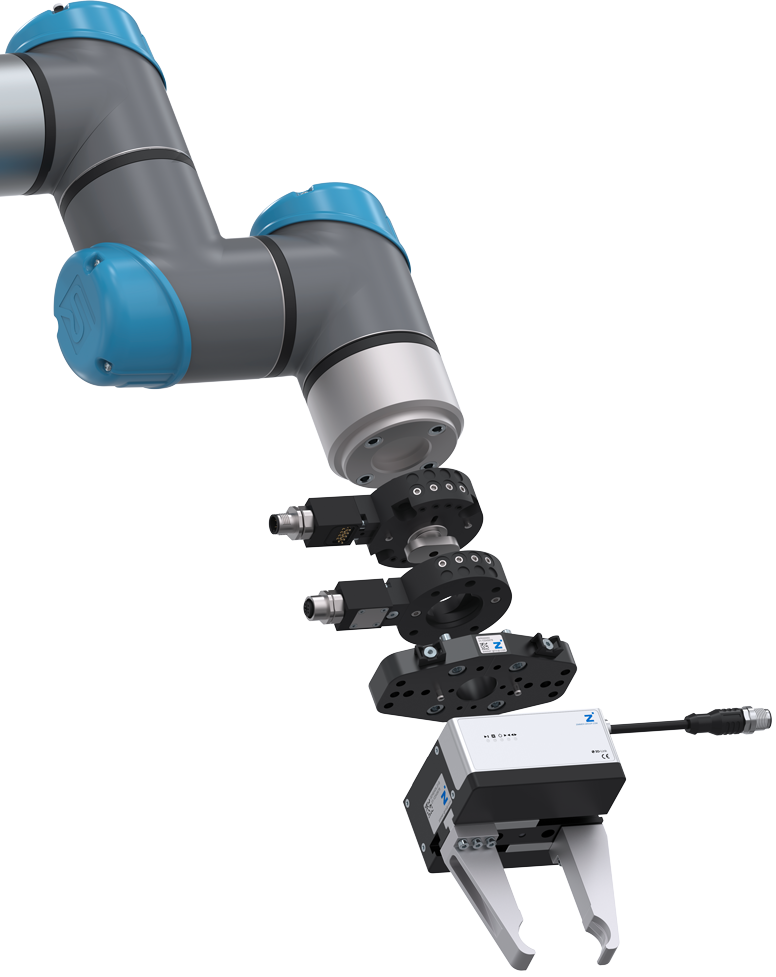

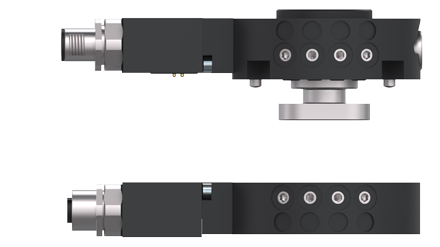

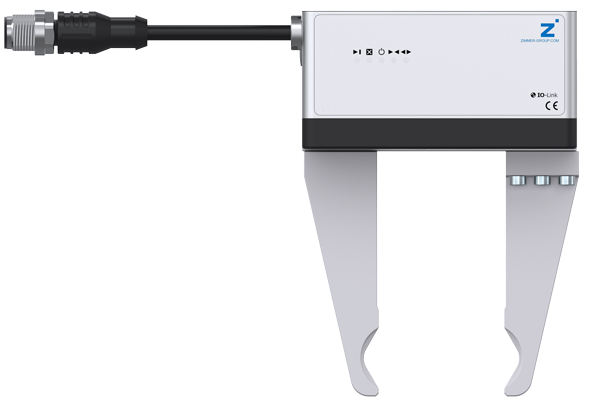

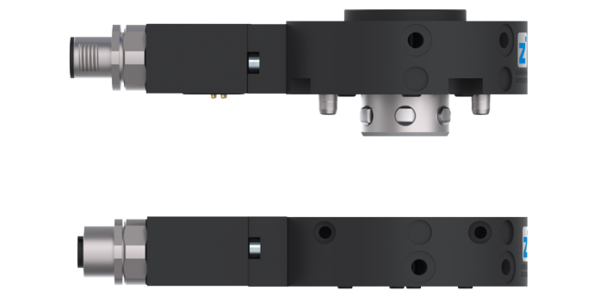

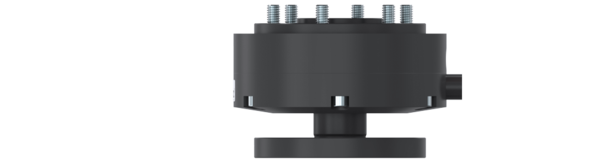

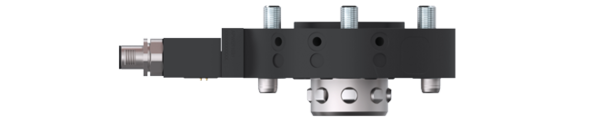

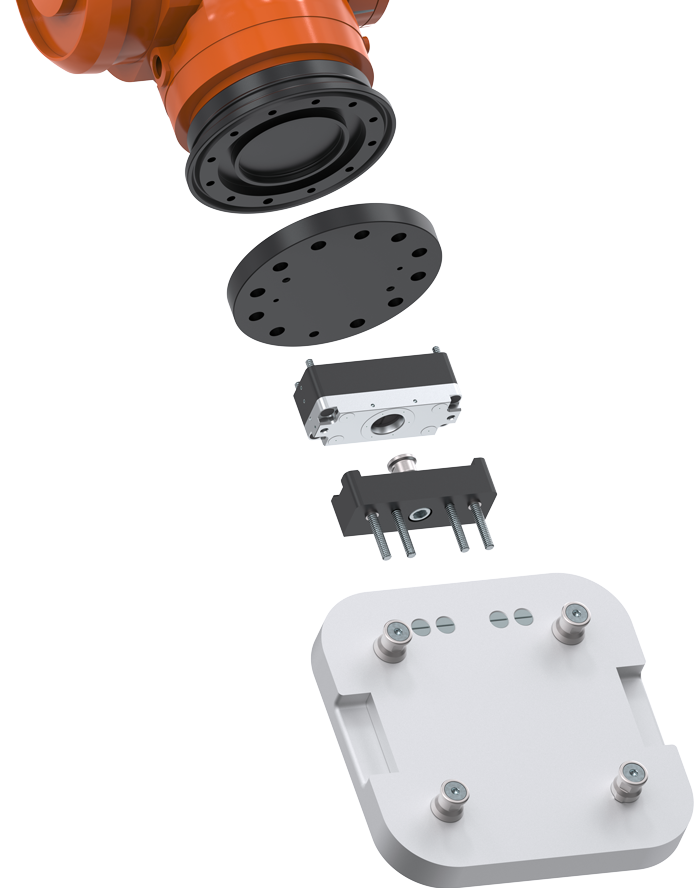

A comprehensive ECOSYSTEM of grippers with a range from normal to large stroke as well as suction and vacuum components can be adapted to the respective workpiece with a great deal of flexibility. Here, even for a low quantity, fast adaption times and simplified servicing of the robot enable the machine loading and thus an optimized, automated production process.

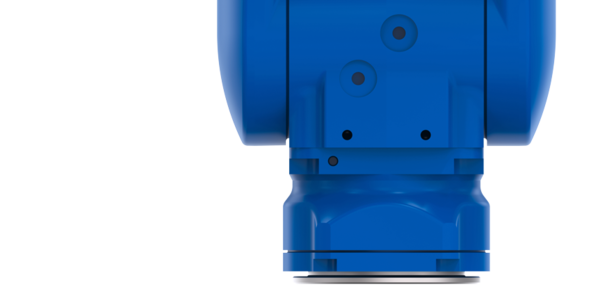

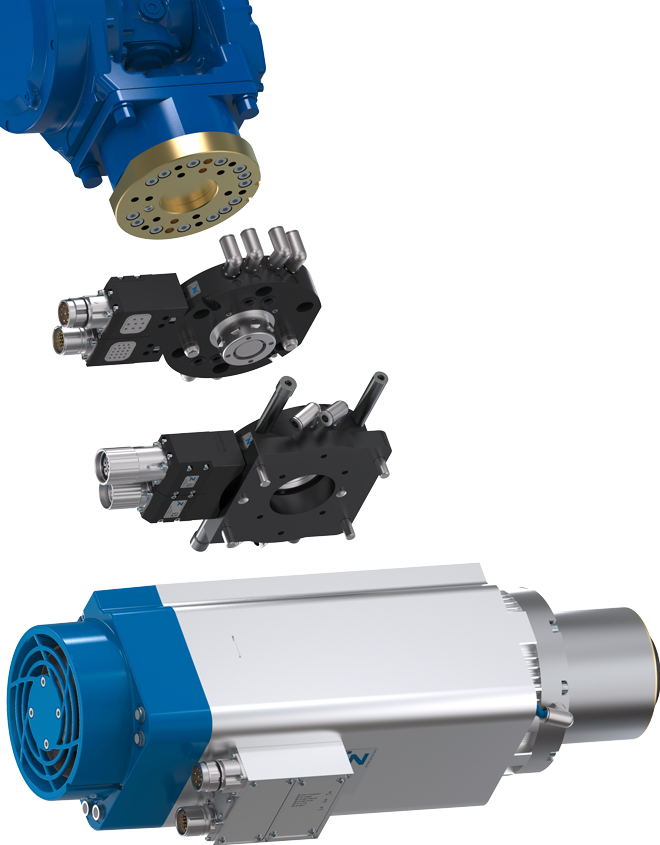

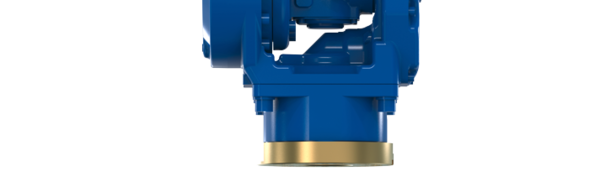

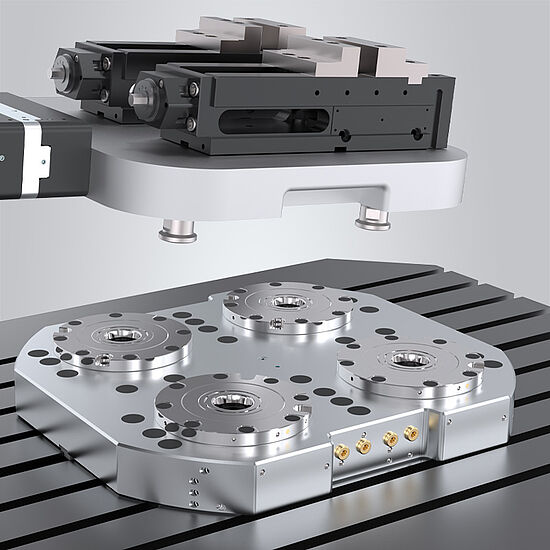

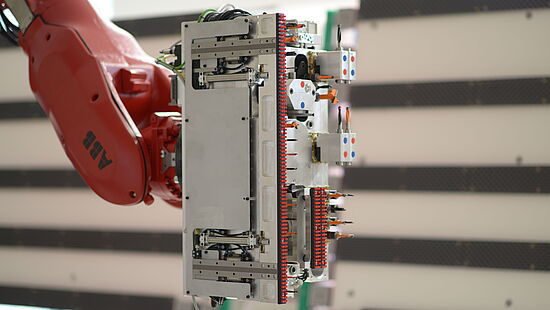

EXAMPLE 2: COLLABORATIVE WORKPIECE INSTALLATION

In this application, production is effectively supported by the collaborative robot with end effector. Specific programming knowledge is not necessary due to intuitive software. This ensures easy commissioning and the fastest adaptation times.