E-mobility

Zimmer Group offers handling solutions for all areas of e-mobility

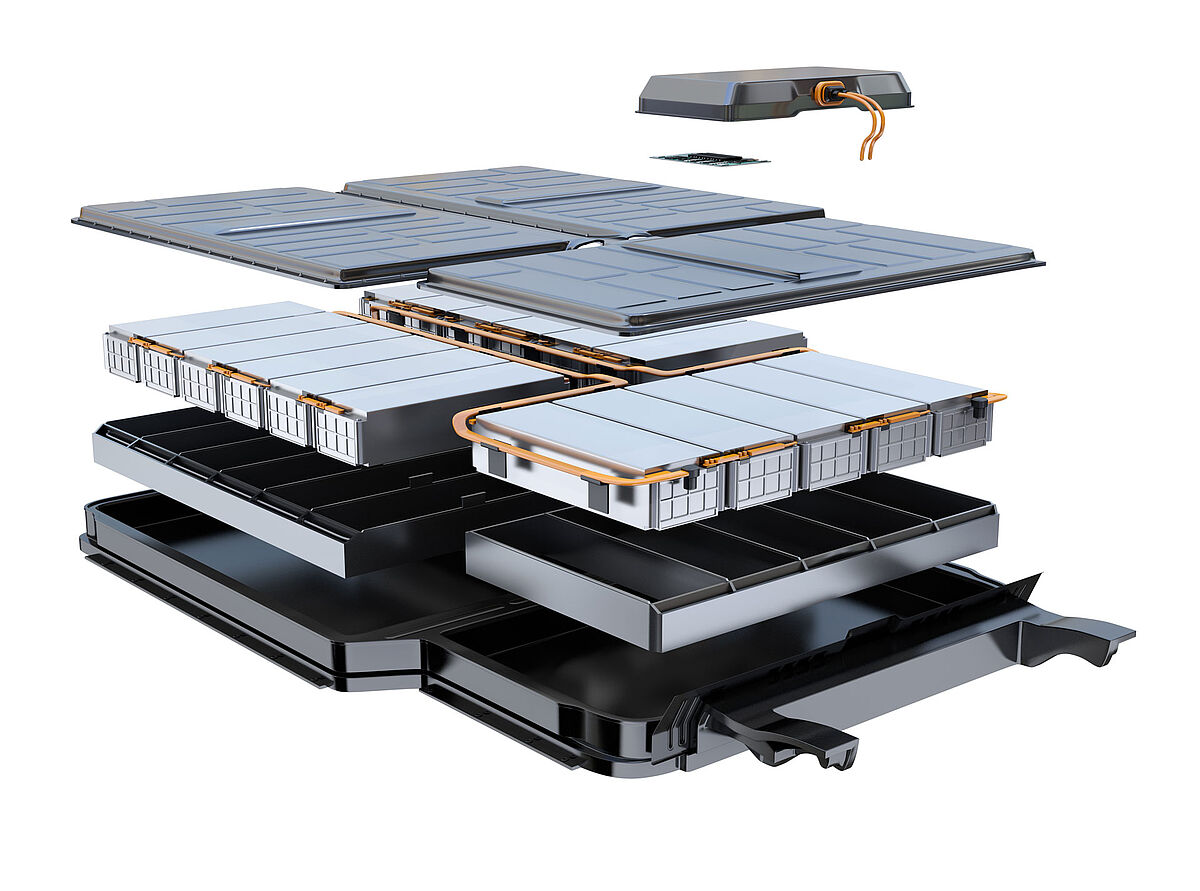

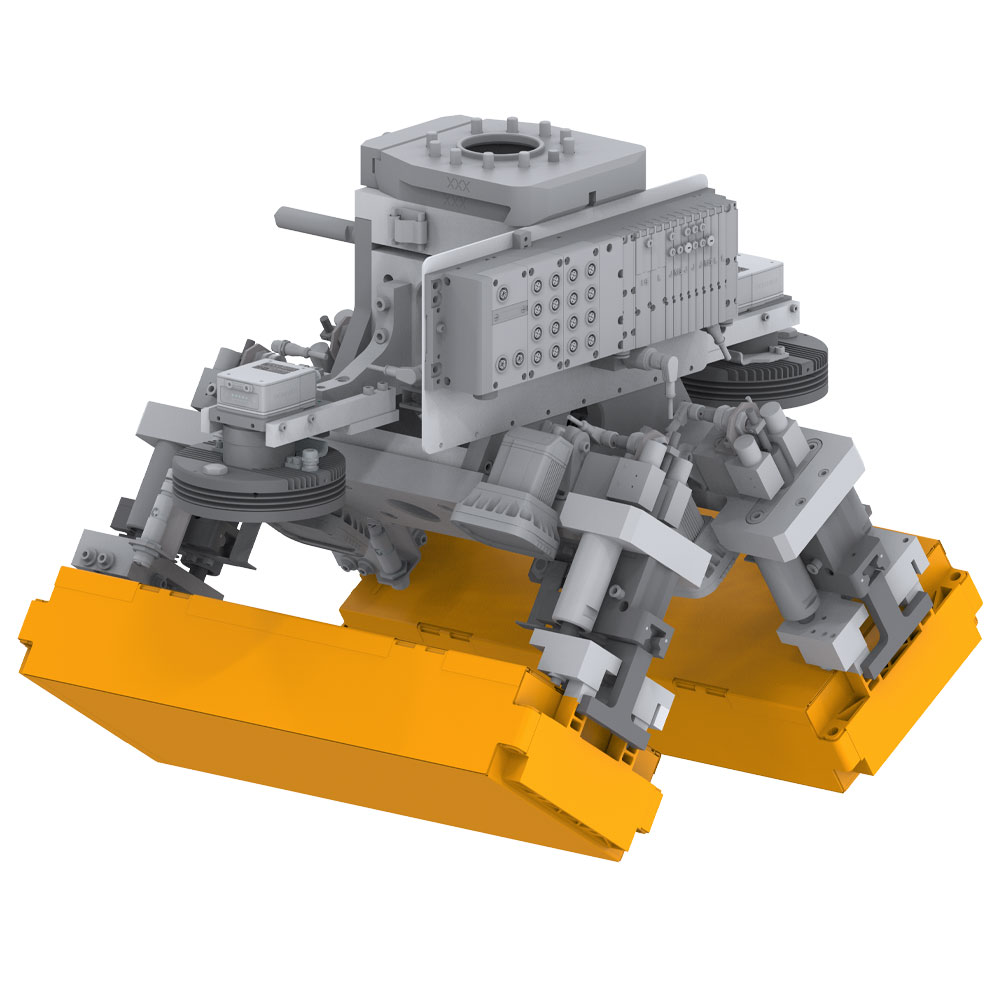

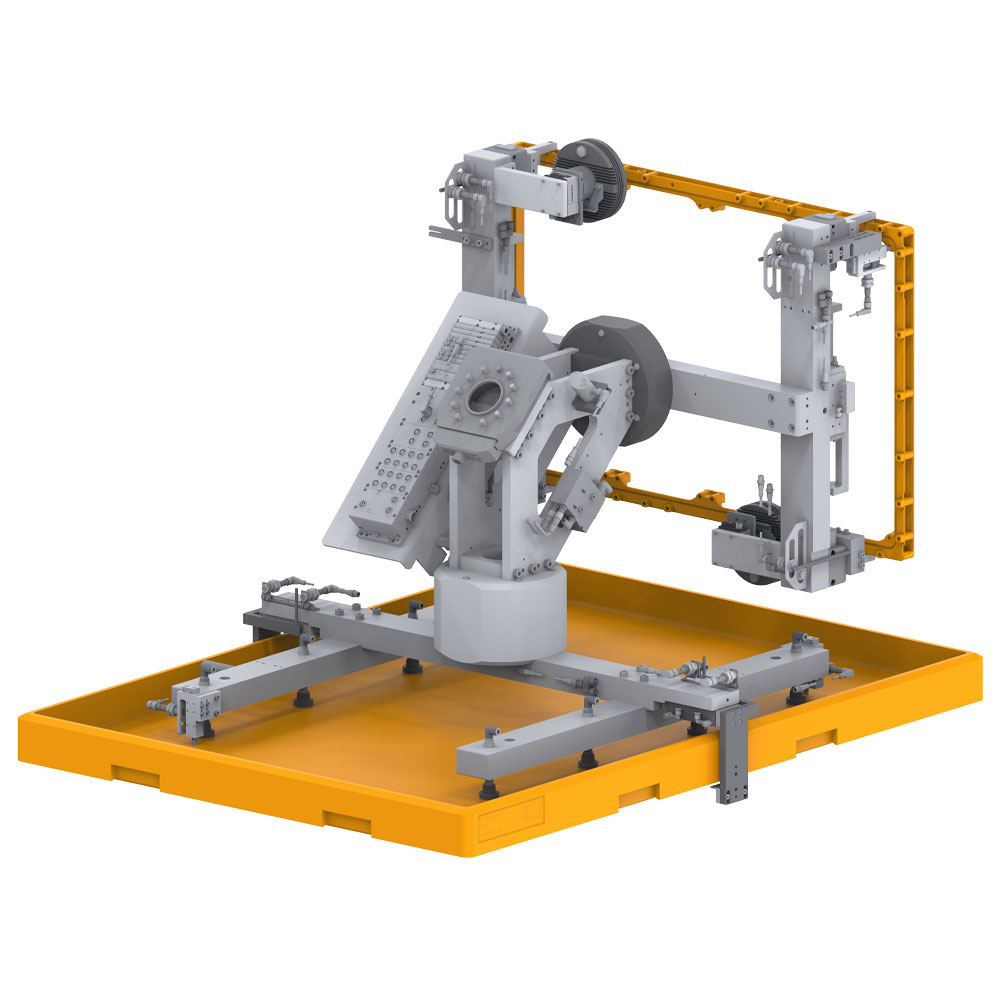

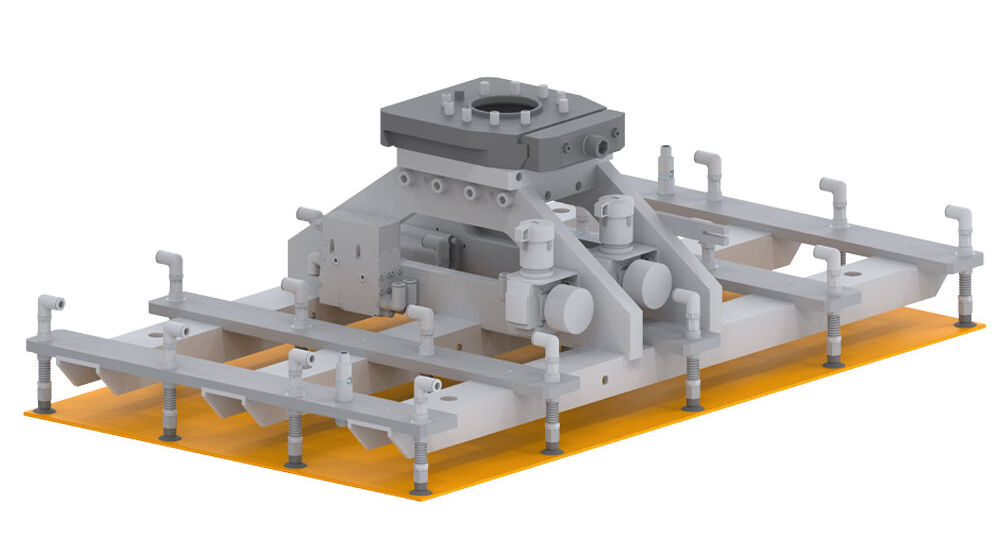

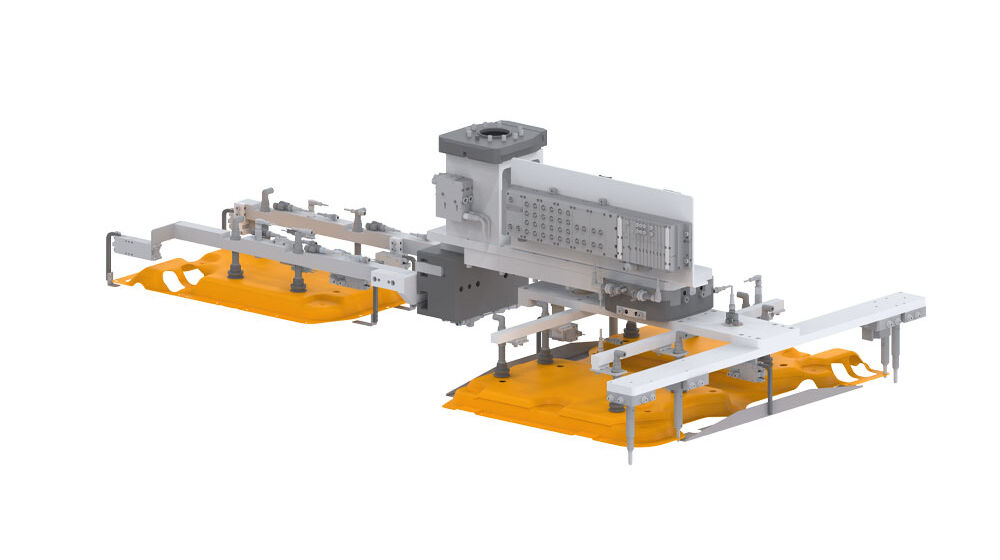

The production of electric vehicles imposes new requirements on production technology. Producing battery cells and packages economically is an important factor in ensuring that this market can grow successfully. For this purpose, a high degree of automation—as it already exists today in motor production—is absolutely critical. The competition for the best production technology has been underway for a long time. Zimmer Group is a development and system partner to many major-name premium manufacturers and systems manufacturers in battery production, module assembly and electric motor production.

- Implemented projects:

50 projects, 400 grippers, 2000 devices - E-mobility solutions since 2014

- Engineering expertise:

More than 100,000 hours of engineering - Highlights:

Development partner of premium automotive, OEMs and systems manufacturers

Today, reducing CO2 emissions is more important ever. From electric scooters to electric trucks. Zimmer Group offers solutions for all areas.

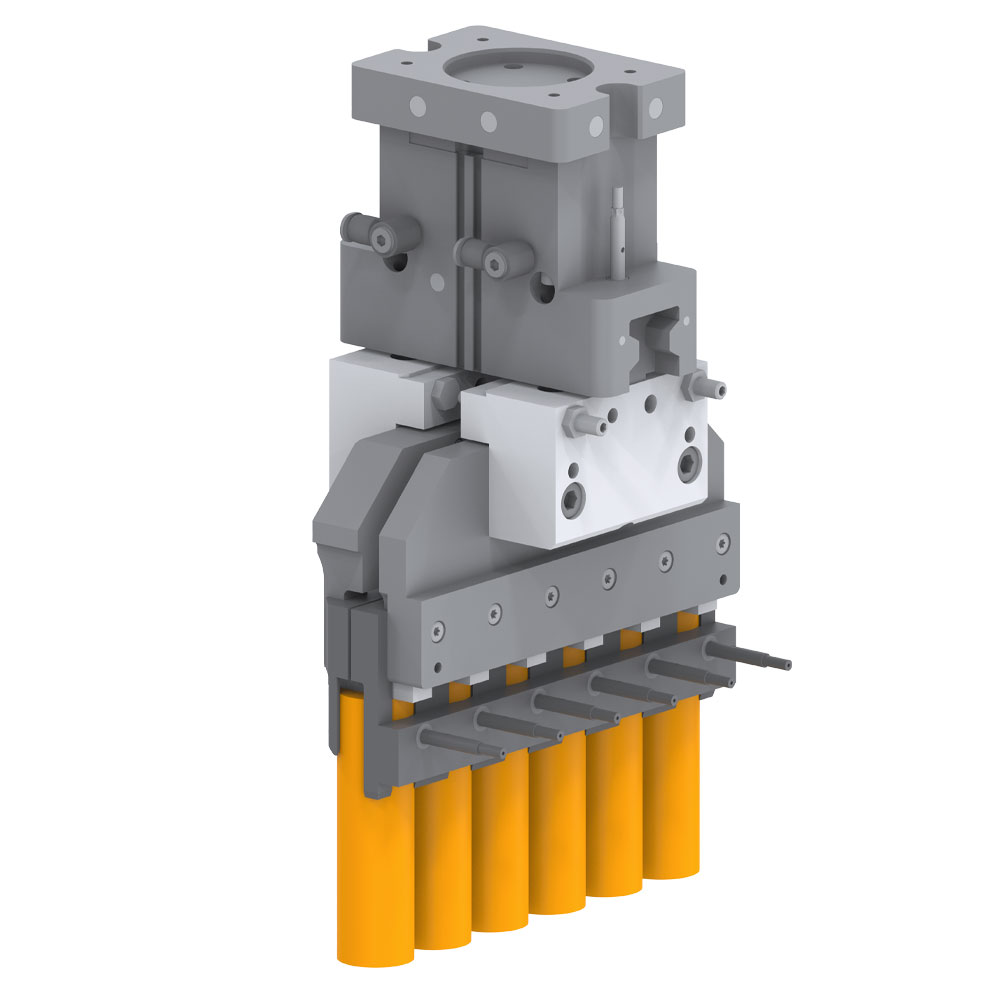

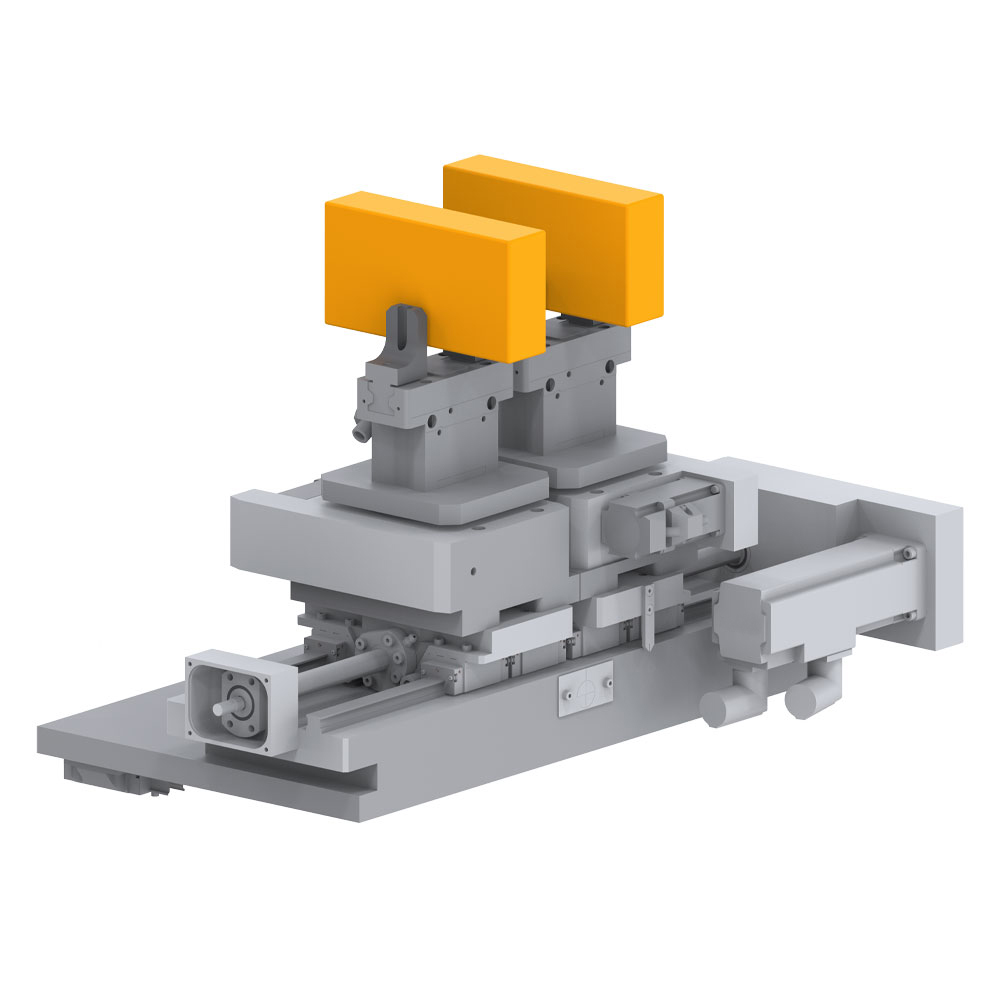

MAGNETIC GRIPPERS FOR CYLINDRICAL CELLS

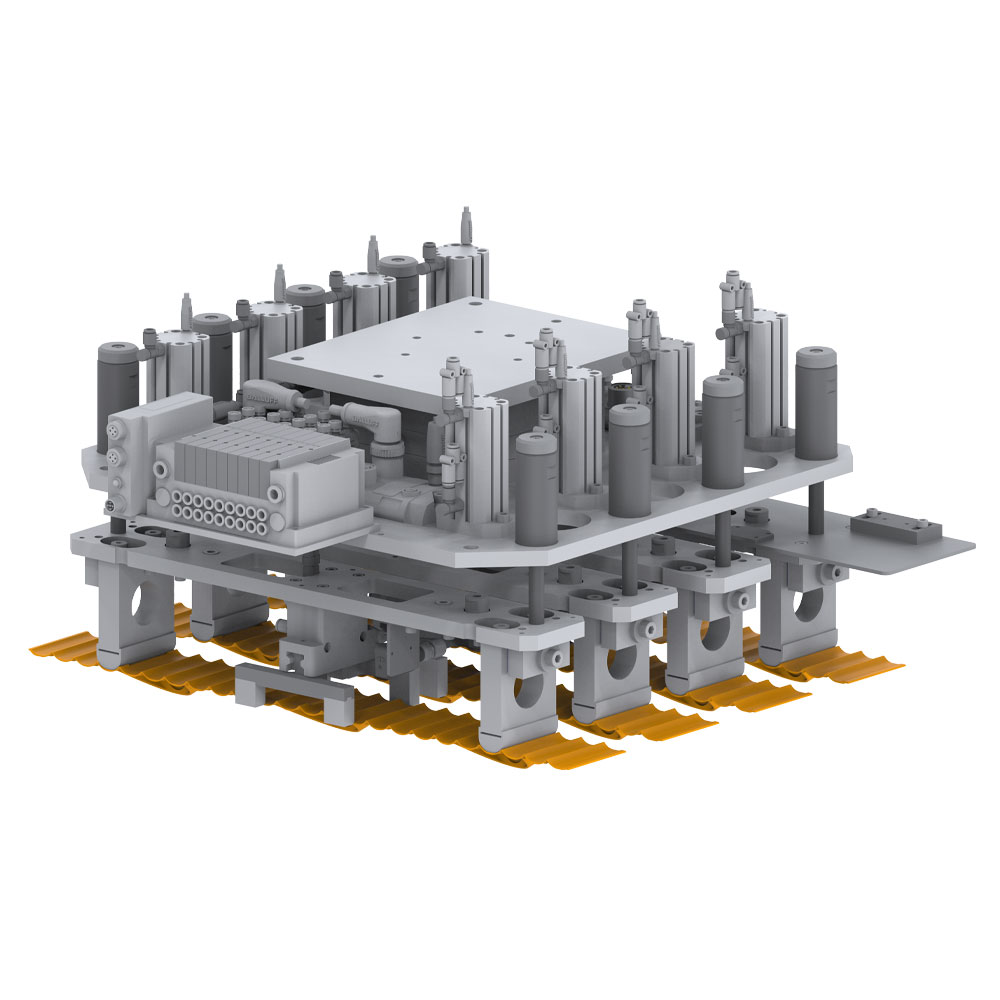

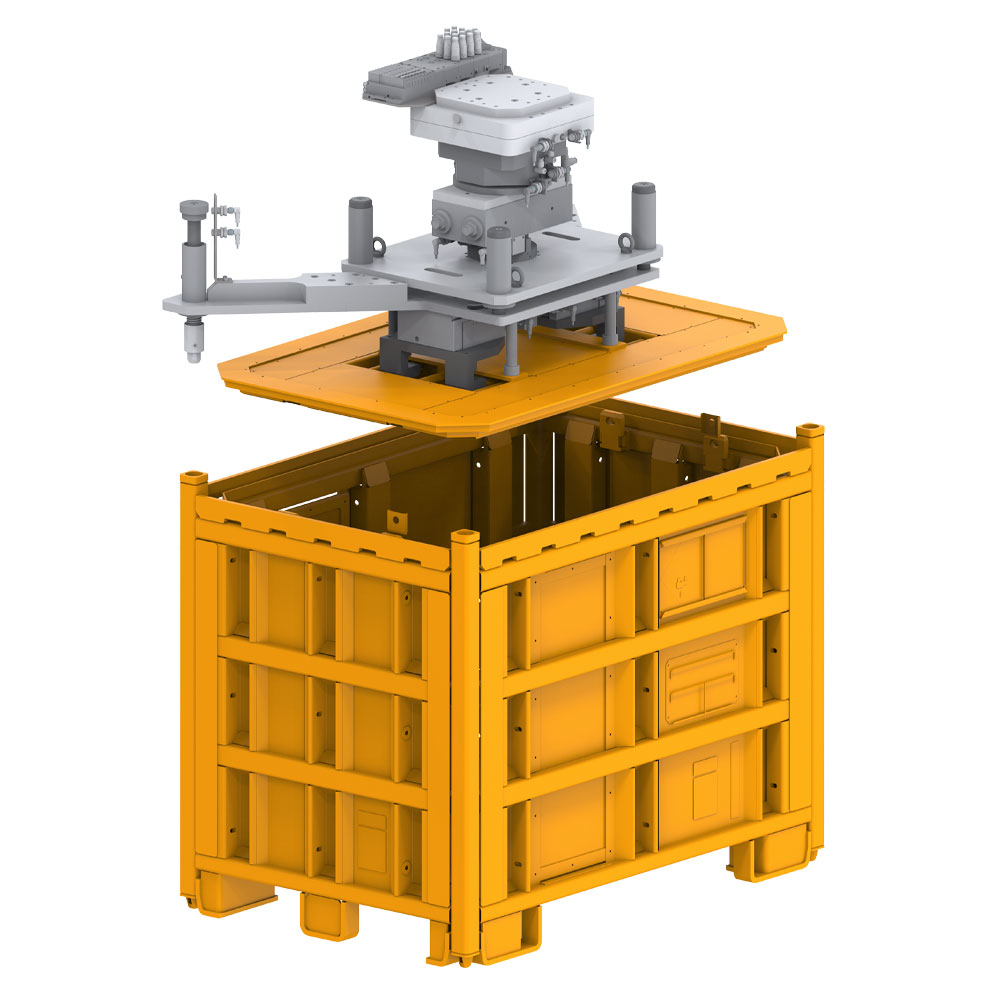

CELL PRODUCTION FOR E-MOBILITY

SPACE SAVING AND POWERFUL

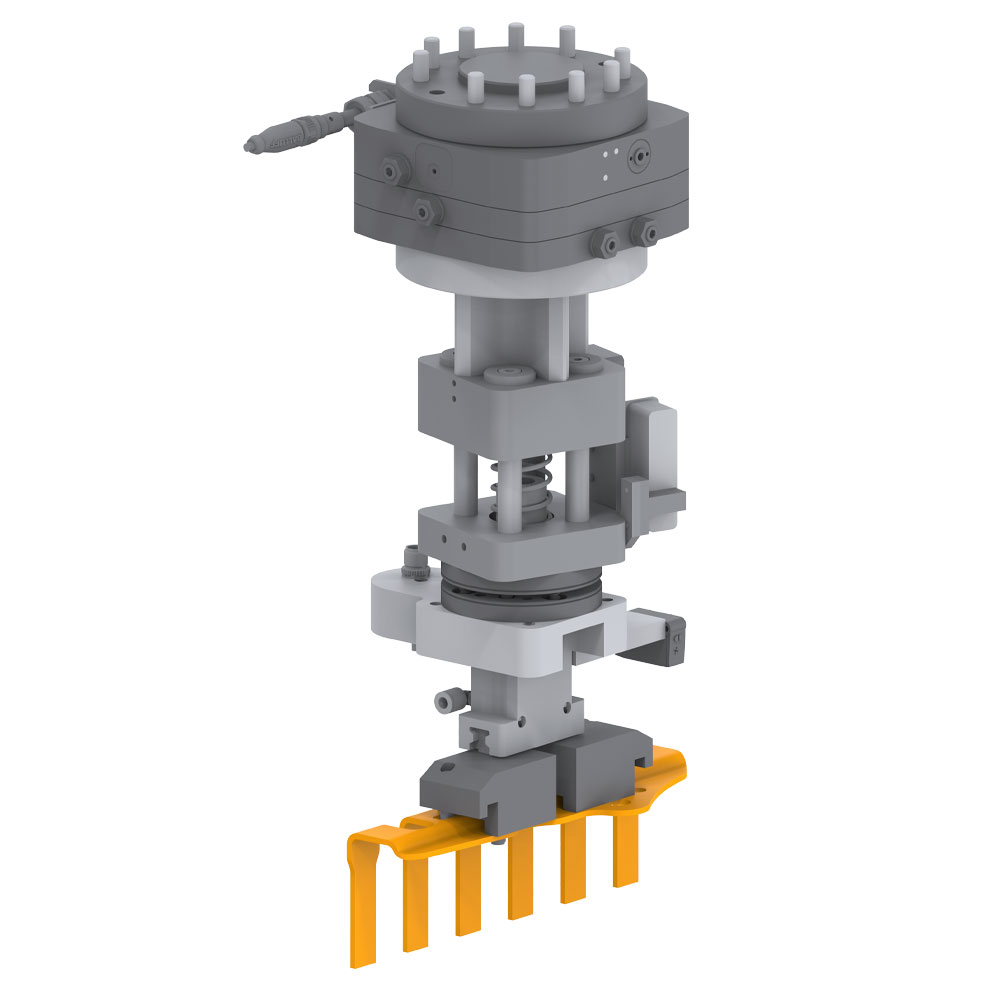

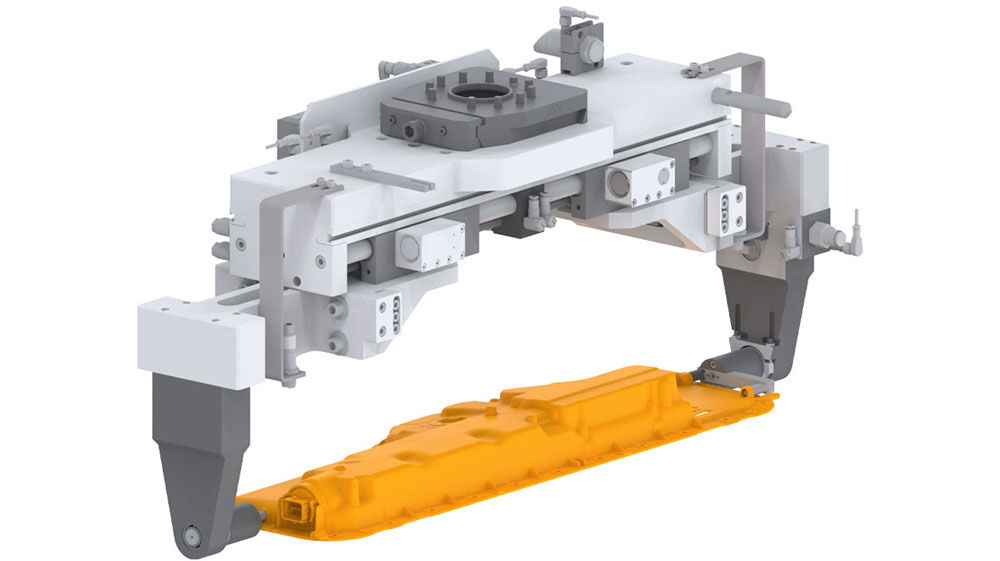

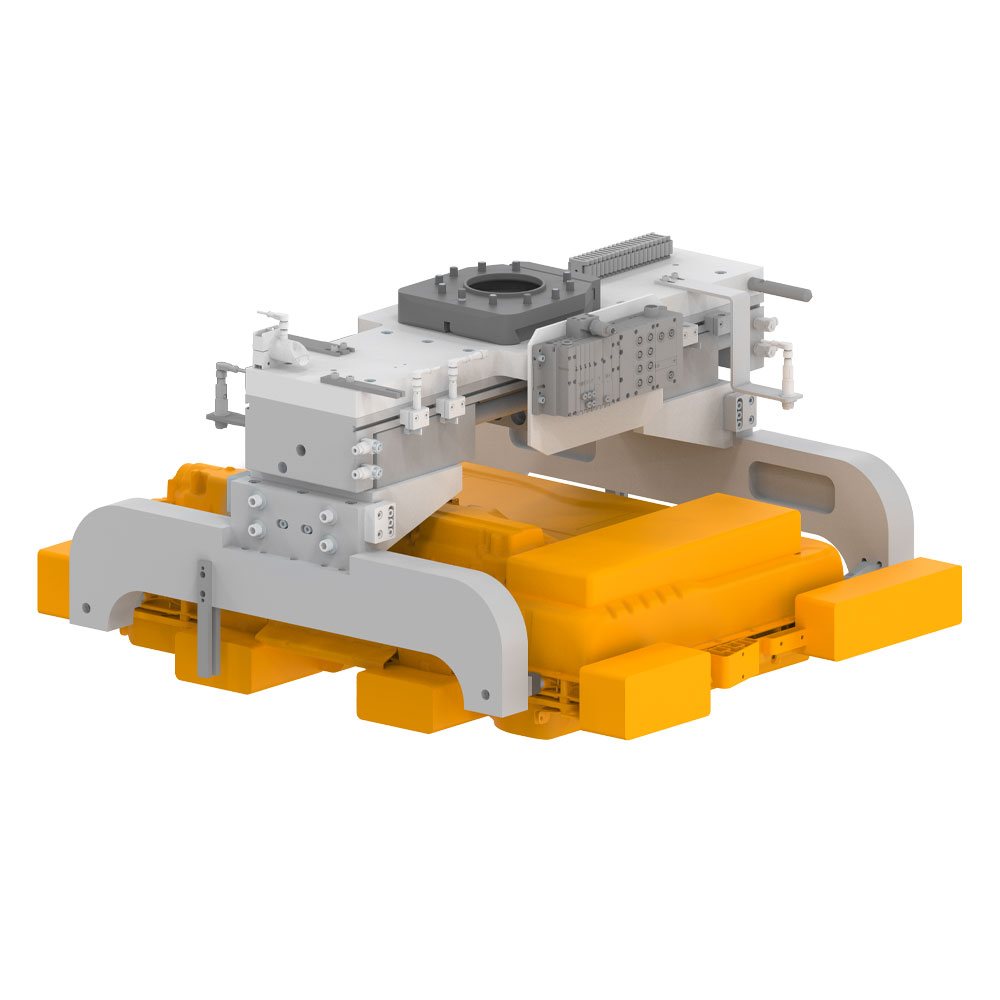

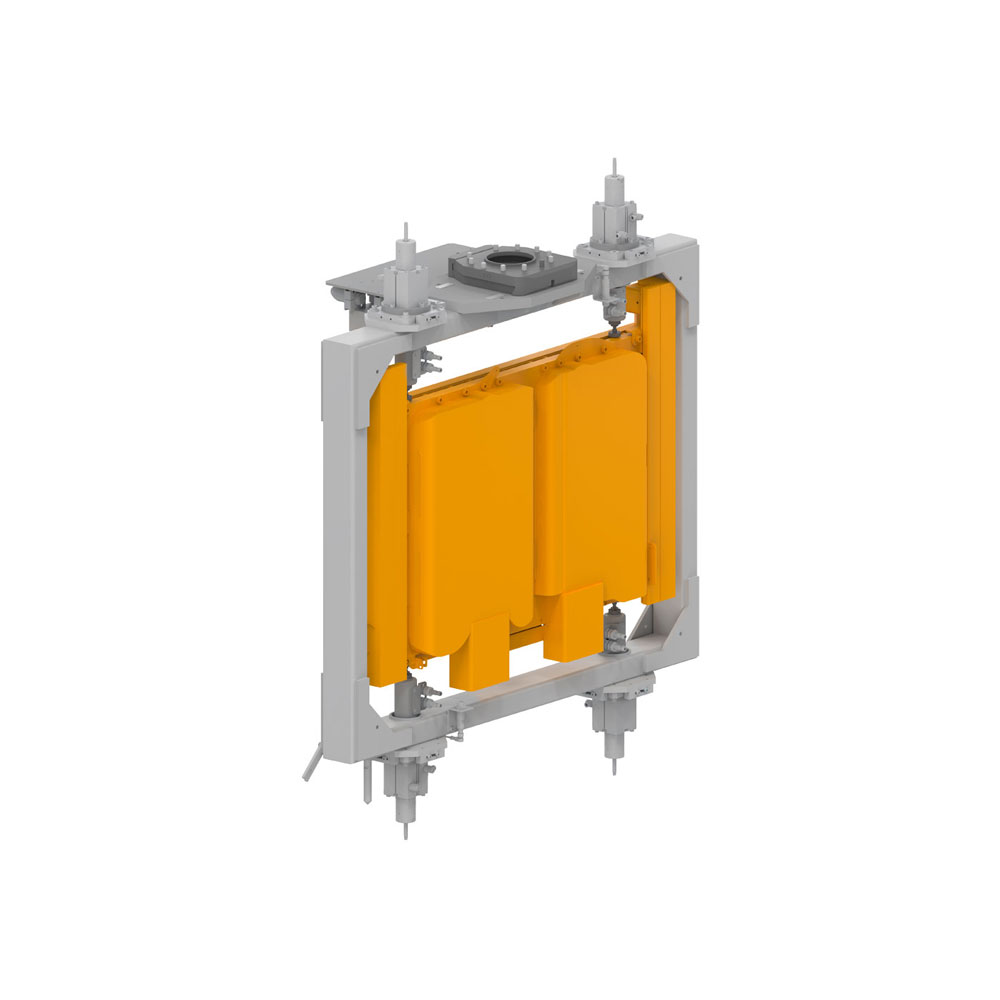

The gripping of cylindrical cells during the production of electric vehicles represents a particular challenge. The cylindrical cells must be nested in this process, which means they consolidated as closely as possible to enable optimal use of the limited space in the vehicle. This is only possible when the gripper is located in the shadow of the battery.

This process-relevant design was implemented and combined with a holding force of 65 N, which ensures that the cylindrical cells will be held securely even at the highest accelerations and during an emergency stop. The low residual holding force under 1 N when the magnets are deactivated not only enables reliable depositing. It also fulfills the requirements for technical cleanliness.

The focus is on modular thinking to enable the gripper to be optimally adapted to the respective process. The gripper can be combined with piston position sensing as well as battery presence sensing. Moreover, axis compensators are available that work together with the centering plates to compensate cell misalignments that can occur in the various production processes.

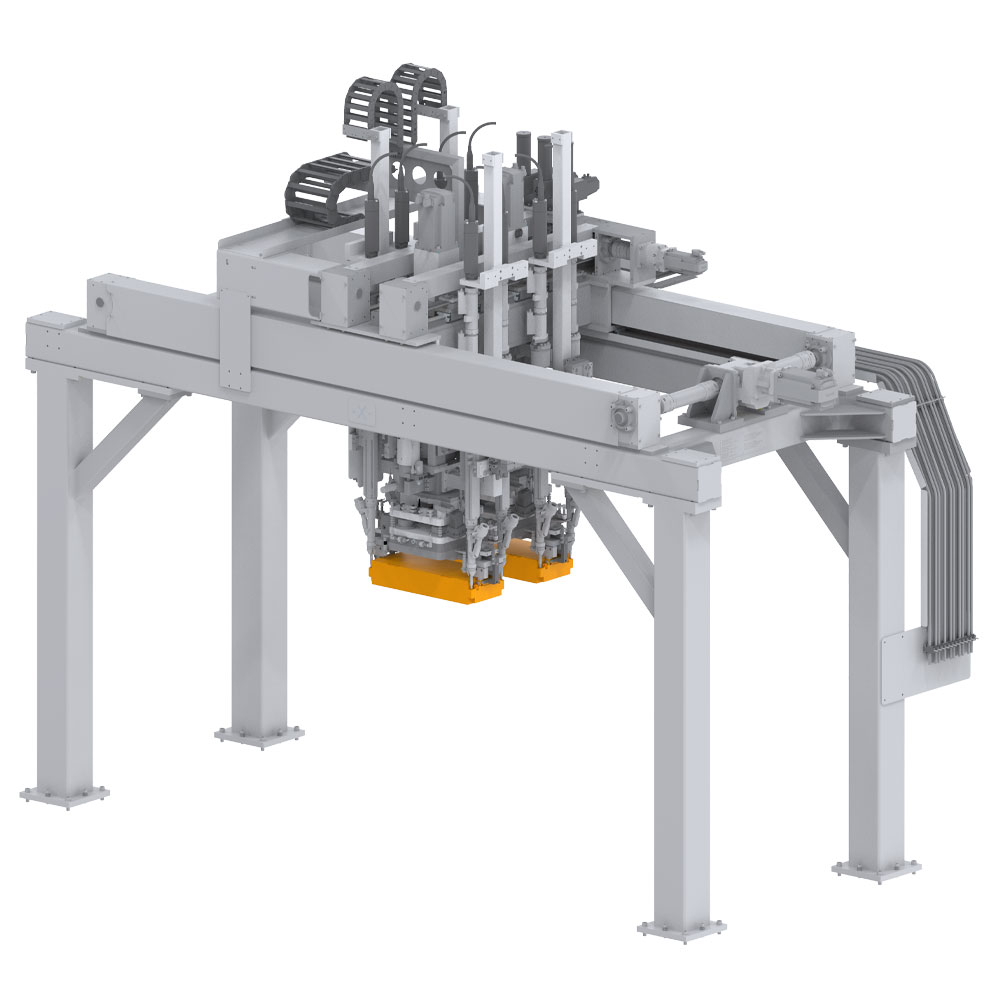

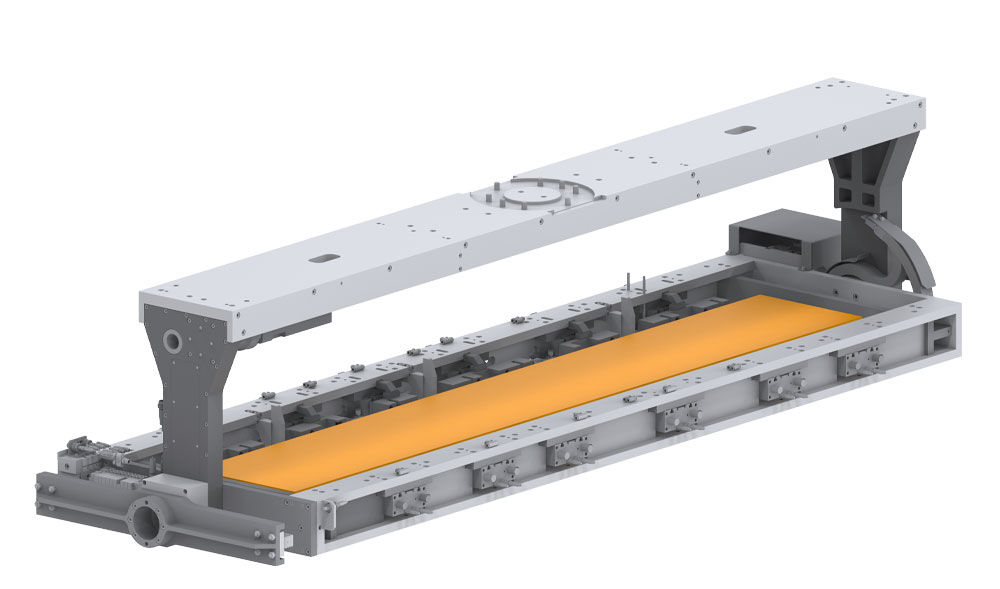

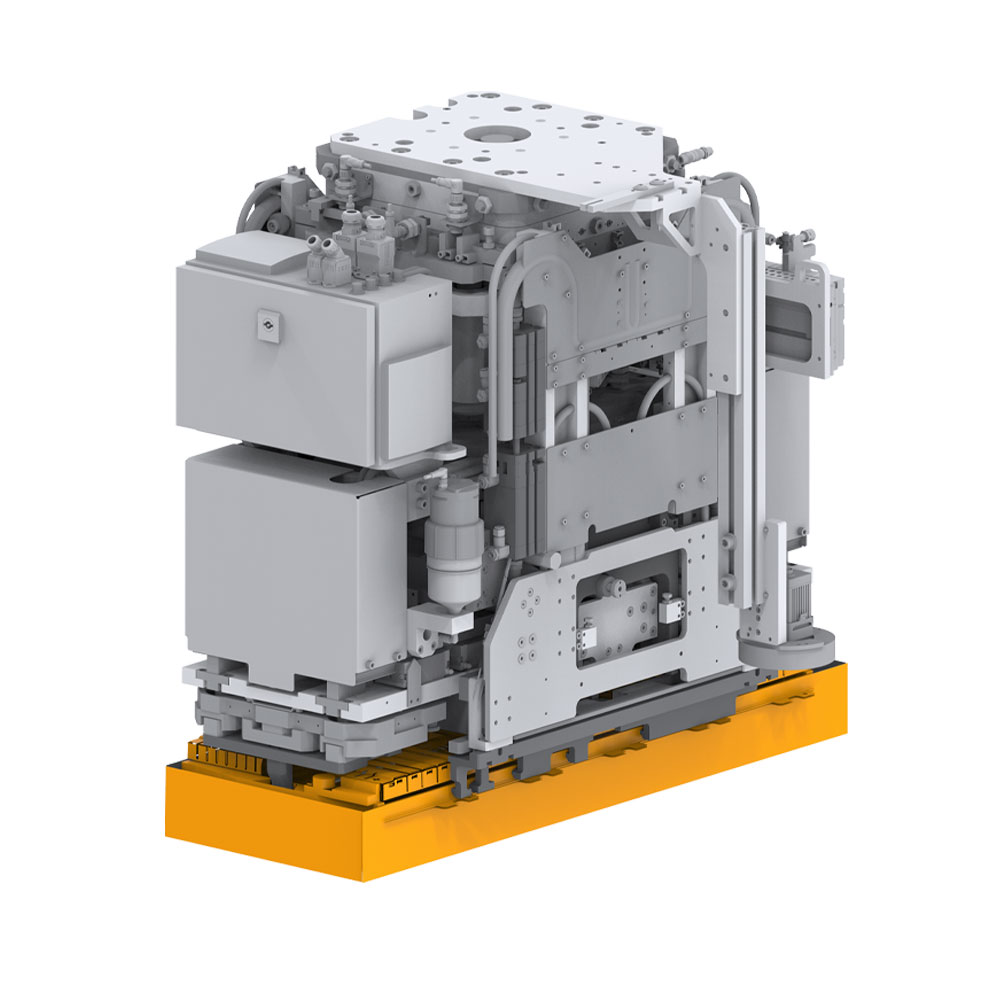

Zimmer Group solutions aren't just limited to a few grippers. The KNOW-HOW FACTORY is continuing this modular concept further in order to provide ready-to-install systems that can cover all processes used in sophisticating manufacturing.