AC SERIES COMPACT AXES

LINEAR DRIVE FOR YOUR HANDLING PROCESSES

Compact axes are a crucial element in modern automation technology. The space-saving design of the AC series enables a high level of manufacturing flexibility and efficiency in the most varied application areas. It combines precise linear movement with powerful, integrated drives – and in a tiny amount of space. This allows it to be easily integrated into existing systems and combined together without problems. It thus increases the cost-effectiveness and performance of your automated processes. High speed and rapid acceleration also mean that you do not have to make any compromises in performance, even in tight space conditions.

Discover the advantages of the AC series and learn how you can bring your production efficiency up to a new level!

SIMPLE CONFIGURATION

Two installation sizes: 40 and 60.

Control: IO-Link or CANopen.

Clamp: Optional in NC design.

WHAT'S INSIDE

THE TECHNICAL FEATURES IN DETAIL

MAXIMUM PERFORMANCE IN MINIMAL SPACE

TAKE ADVANTAGE OF THE BENEFITS OF THE AC SERIES

Flexible control:

IO-Link for simple commissioning and implementation of simple applications or CANopen for interaction with other machine elements in real time.

Standard ball screw with BLDC motor:

For rapid and powerful movements with high precision.

Optionally with safe torque off function:

Maximum safety thanks to fast and reliable torque shutoff.

High load capacity and service life:

Thanks to a linear guide with a double rail carriage and one-piece slide milled from solid material.

Customized movement profiles:

Freely configurable parameters allow movement that is perfectly adjusted to your application.

Low space requirement:

Compact design without interference contours with an unbeatable installation size and stroke ratio.

Absolute precision:

High positioning and repeat accuracy without reference runs thanks to an integrated, absolute position measuring system.

Minimal maintenance requirement:

Lubrication intervals from up to 5 million cycles at up to 100 million-cycle service life.

Low operating costs:

Motor shutoff at a standstill even in vertical applications possible by combining it with a clamp.

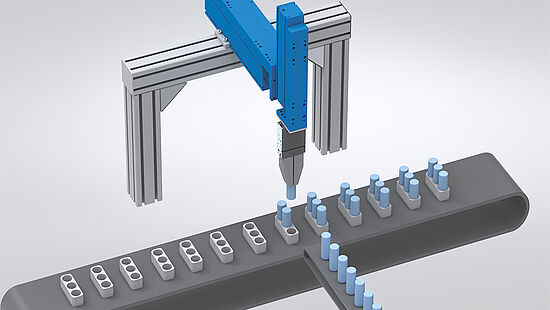

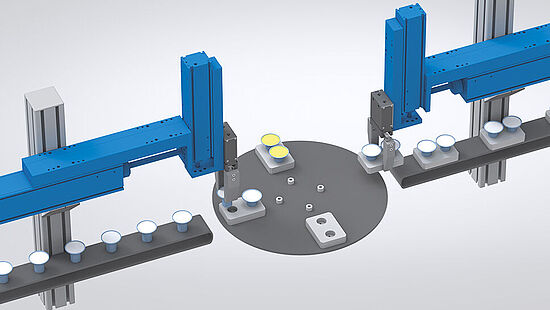

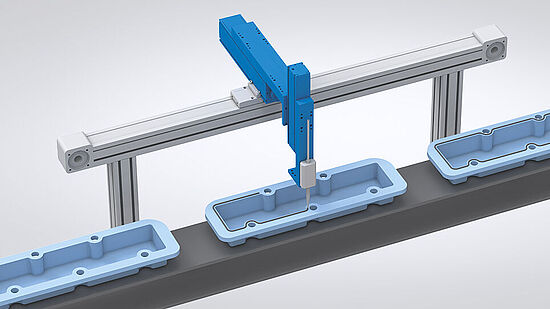

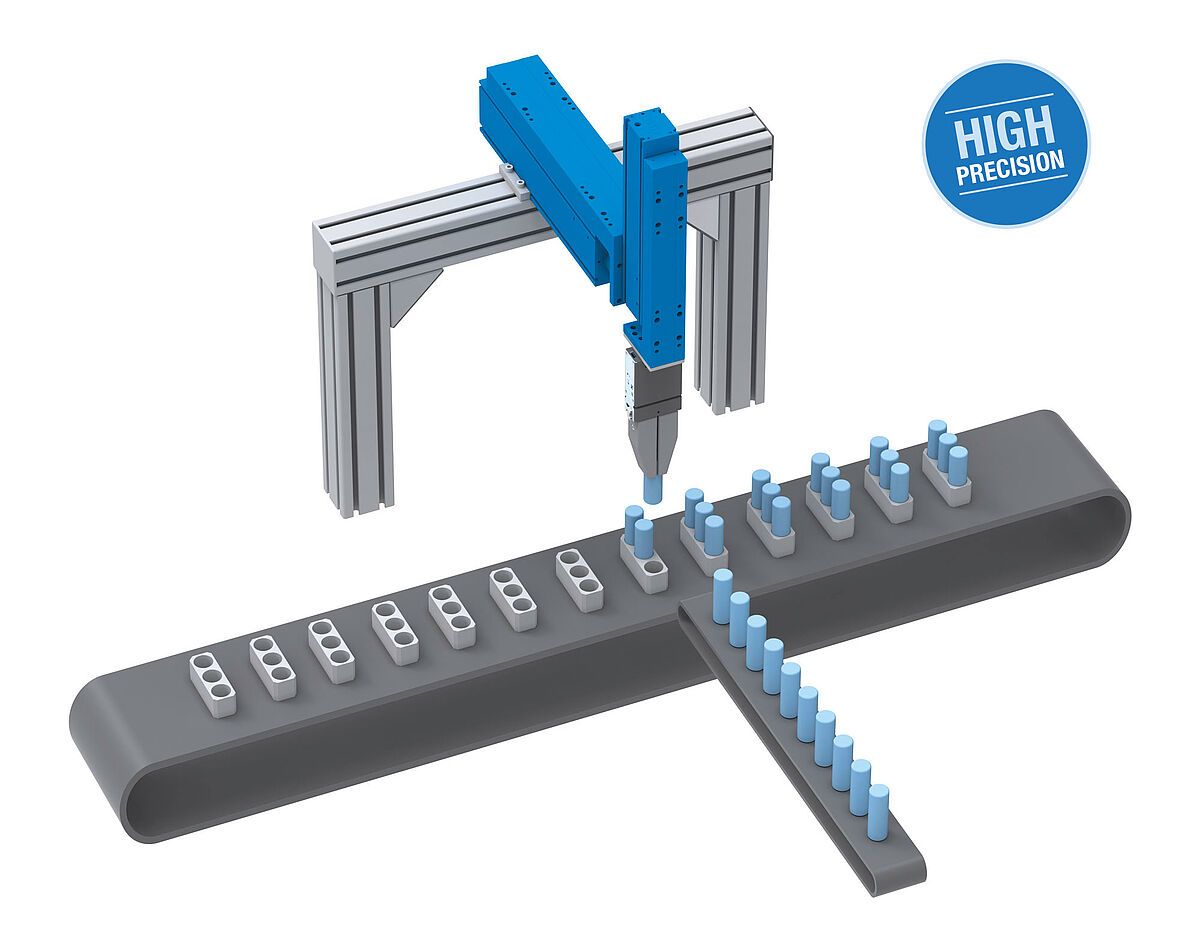

THE COMPACT AXES IN USE

COMBINATIONS FOR EVERY APPLICATION

FAST, PRECISE, REPEAT ACCURACY

Our compact axes are integral parts of automated processes in many industries. They are ideal for applications in which fast, precise and accurately repeatable movements are needed – and they can do this millions of times over. The following examples provide you with a detailed insight into specific applications of compact axes and demonstrate how they can increase the efficiency and precision of your automation processes.