Winner in all (performance) classes

The motor spindle is one of the essential assemblies of a tooling machine, a milling center or a robot-based end-of-arm solution. It achieves maximum productivity and precision, thereby enabling optimum performance and workpiece quality. The mechanically integrated motor solutions are extremely compact, highly productive and achieve maximum rigidity, the prerequisite for maximum speeds and precise concentricity.

The Zimmer Group offers you the perfect portfolio for this. Regardless of whether you are looking for a motor spindle for use in milling machines or machining centers, you will find economical standard motor spindles, air-cooled spindles in the low and medium performance range, as well as fluid-cooled high-performance spindles and, of course, the right accessories from inverters to cooling units, C-axes and connection sets in our various spindle kits.

- Air- and water-cooled high-frequency spindles in various performance ranges

- Support on topics such as power dimensioning, energy supply, cooling or integration into the control system or service

- Repair and on-site service by expert personnel

- Spindle IO-Link communication module enables condition monitoring or predictive maintenance

- Extremely high reliability, high power density and broad compatibility

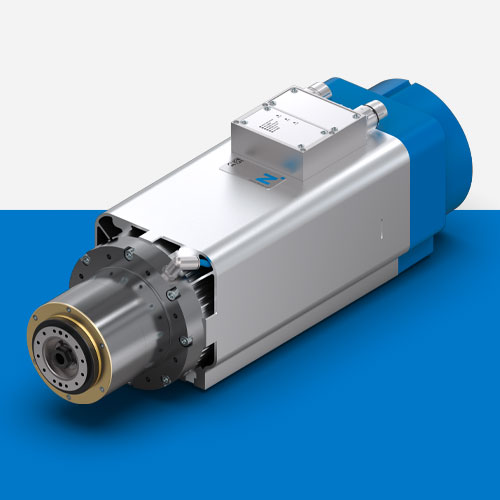

AIR-COOLED

Air inlets and a sufficient air circulation volume are the ideal prerequisites for spindles with a high power density.

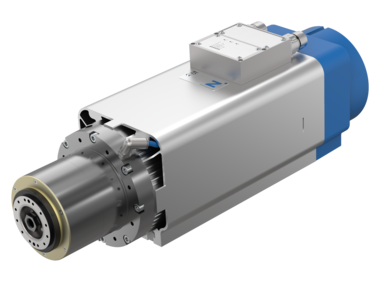

Water-cooled

Water cooling and dimensioned cooling units ensure highly productive spindles thanks to optimized temperature control.

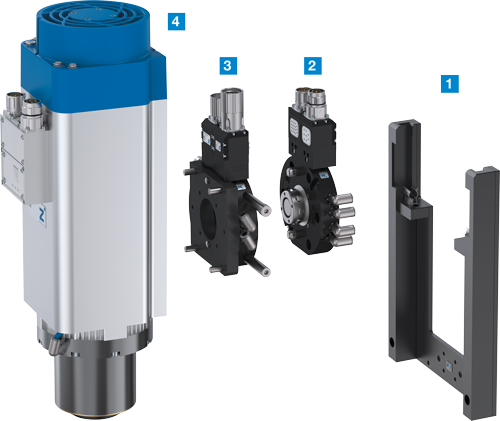

Robot change units

The WWS series enables a fully automatic change of motor spindles.

Air-cooled motor spindle HF145-001

- 6 kW/8 kW/12 kW

- 24,000 rpm

- Automatic tool change

- Ideal for machining wood, plastics, lightweight metals and composites

- Optionally with coordinated interface (e.g. for C-axes)

- Optionally with vector control

- Optional changing unit for robot

Water-cooled motor spindle HF125-002

- 9 kW/12 kW

- 24,000 rpm

- Automatic tool change

- Ideal for machining wood, plastics, lightweight metal and composites

- Optionally with vector control

- Optionally with changing unit for robot

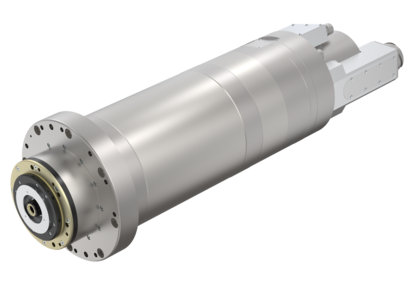

Water-cooled motor spindle HF150-003

- 15 kW

- 26,000 rpm

- Manual or automatic tool change

- Ideal for machining wood, plastics, lightweight metals and composites

- Optionally with coordinated interface (e.g. for C-axes)

- Optionally with vector control

Water-cooled motor spindle HF150-005

- Synchronous and asynchronous variants

- 20 kW

- 24,000 rpm

- Automatic tool change

- With vector control

- Very high power density and torque due to synchronous motor

- Ideal for machining wood, plastics, lightweight metals and composites

Water-cooled motor spindle HF205-006

- 34 kW/48 kW

- 14,000 rpm / 6,000 rpm

- Automatic tool change

- With vector control

- Adapted for use in tooling machines

- Very high power density and torque due to synchronous motor

- Ideal for machining brass, aluminum, steel and cast iron

ROBOT CHANGE UNIT

- Specially designed robot changing units are available for spindles intended for robot use

- Robot changing units form the reliable interface between the robot and the motor spindle

- The loose part is attached to the motor spindle; the stationary part is mounted at the end of the robot arm

- A special storage station is available when the motor spindle is not in use: Automated coupling mechanism, extremely flat design, mechanical self-locking, transmission of compressed air, transmission of power and signals to operate the motor spindle

- Storage station

- Tool changer stationary part

- Tool changer loose part

- Motor spindle

Technology highlight: Motor spindle, HF150-003 series

OUR EXPERTISE – YOUR ADVANTAGE

- Maximum performance: The highest performance standards for these motor spindles are met due to the exclusive use of vacuum cast, hand-wound, high-performance motors from German manufacturing.

- Maximum workpiece quality: With speeds of up to 26,000 rpm and an optional vector-regulated 14.5 kW motor, these motor spindles are best suited for machining various materials such as wood, plastic, light metal or composites.

- Highest productivity meets highest precision: This mechanically integrated motor solution is extremely compact, highly productive and achieves maximum stiffness.