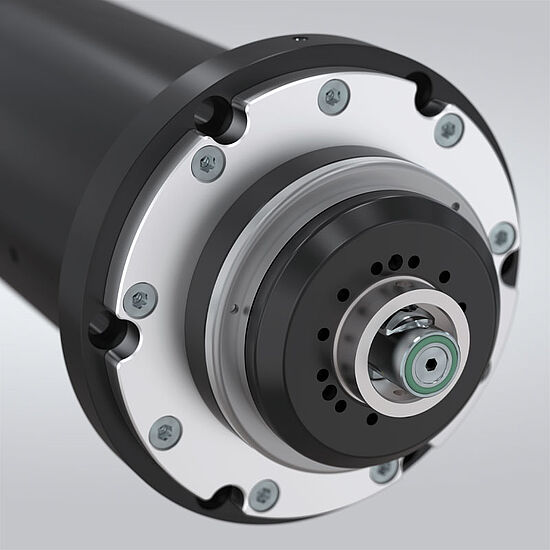

Motor spindles

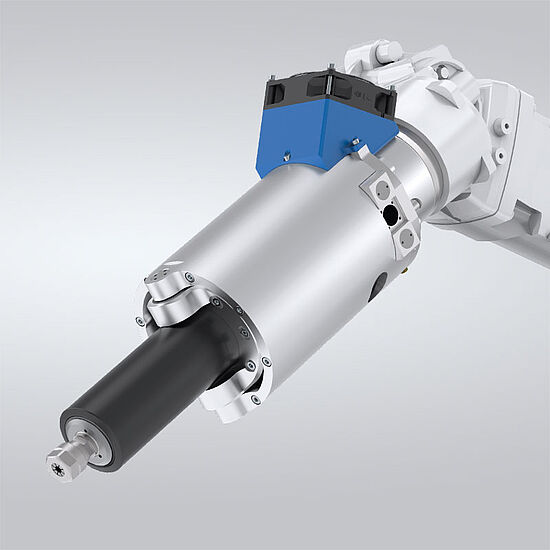

Their compact design, easy maintenance and high reliability make our motor spindles an important component in modern tooling machines and industrial robots. Regardless of whether you are looking for a motor spindle for use in milling machines or machining centers, you will find both air-cooled spindles in the low and medium performance range as well as fluid-cooled high-performance spindles.

Innovative motor spindles and customized solutions

The Zimmer Group is a manufacturer of high-quality motorized spindles that, together with matching accessories and peripherals, offer everything you need for maximum precision and performance in your production. Our portfolio includes not only a wide selection of standard motor spindles, but also the development of individual, customized solutions that are perfectly tailored to your specific requirements. Our great strength lies in our ability to develop innovative and flexible solutions that not only meet the highest technological standards, but also significantly increase the efficiency and productivity of your applications. With decades of experience in the industry, we offer you customized products that have impressive precision and durability. No matter how complex or specific your requirements – together we will find the perfect solution for your success!

The advantage lies in our flexibility

The combination of customized motor spindles with various change systems such as our WWR and WPR tool changers opens up completely new potential and ensures maximum adaptability in your production processes. This increases your efficiency and flexibility by allowing you to react to changing requirements at any time.