MATCH – end-of-arm ecosystem

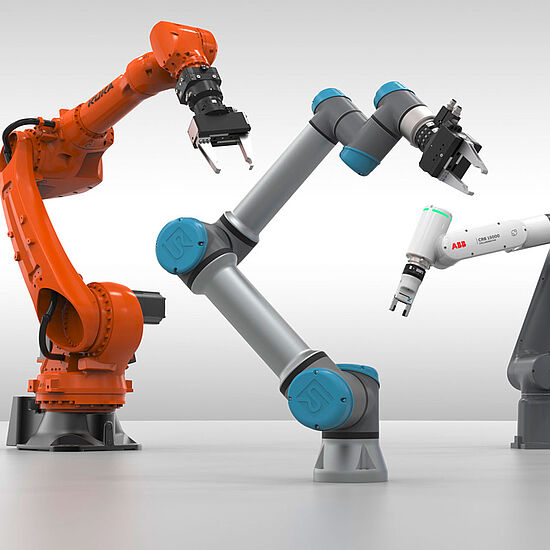

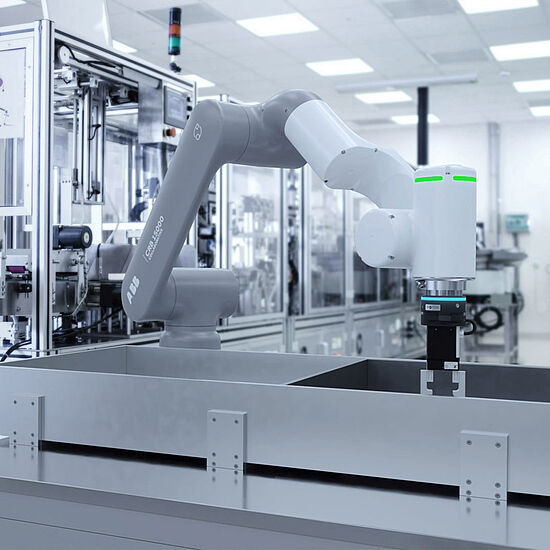

Discover MATCH! The standardized interface combines the two main handling technologies: gripping and vacuum systems. The innovative ecosystem – consisting of robot module, gripper, storage station and suitable software – can be integrated quickly and easily, enabling profitable production in a timely manner, even for small quantities – both in terms of the choice of end effector and the choice of robot. MATCH is compatible with all common robots on the market. Thanks to the standardized interface and the option of a manual or automated changeover function, you are equipped for the constantly changing requirements and challenges on the market.

Technology highlights

FAQ – Questions and answers about MATCH

MATCH is a standardized interface that combines the main handling technologies – gripping and vacuum systems. The fast adjustment times make you perfectly prepared for the increasing demands of the market. Uncomplicated integration lets you get production up and running quickly and profitably, even for small quantities. You have maximum flexibility in selecting both the end effector and the robot. MATCH is compatible with all common robots. Thanks to the standardized interface and the option of manual or automated changes, you are perfectly equipped to meet the dynamic challenges of automation.

Even without the change option, MATCH offers numerous advantages and gets you ready for future challenges. MATCH is immediately ready for use and ready to connect. Intuitive software helps you with commissioning and control – no programming knowledge required. The standardized interface also gives you a wide selection of end effectors. The simple maintenance and service make it easy to enter the world of automation and quickly achieve profitable production, even for small quantities.

The MATCH end-of-arm ecosystem is compatible with leading brands of robots such as ABB, Denso, Doosan, KUKA, Universal Robots, Fanuc, Yaskawa, Stäubli and Mitsubishi. If you are not sure whether your robot is compatible, please contact us.

We offer solutions for almost every user and robot type. If your robot model is not listed, please contact us.

The gripper and robot communicate with each other through the Smart Communication Module (SCM). This module is the interface for the end effector, converting the IO-Link communication system to digital I/Os and vice versa. It communicates directly with the robot controller and lets you control the end effector quickly and easily.

Yes, the SCM is available both without software for self-cabling and as a complete package with cables and software tailored to the specific robot manufacturer. With this package, you can get started right away without any additional work for cabling or wiring.

The Comfort App, which comes with the package and is tailored to your robot manufacturer, lets you control the end effector easily and directly from the robot control panel. All the necessary commands for smooth automatic operation are included.

For simple applications such as opening and closing the gripper, the digital I/O option is a good choice as basic equipment. For more complex applications that require additional force or stroke settings as well as status monitoring, we recommend the intelligent IO-Link version. RS485 is the manufacturer-specific counterpart to IO-Link.

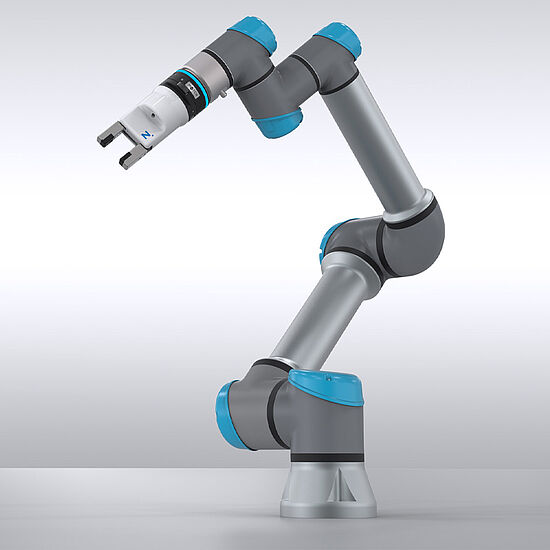

Thanks to the standardized interface of the robot module, you can use a variety of end effectors. Depending on the application, you can use IO-Link grippers with an IO-Link module or digital grippers with a digital I/O module.

Depending on your application, you can choose vacuum components from J. Schmalz or grippers from the Zimmer Group. Thanks to the manual or automated change options, you have both handling technologies to choose from.

If you are not sure which handling component is suitable for your application, please contact us.

The MATCH end-of-arm ecosystem is compatible with leading brands of robots such as ABB, Denso, Doosan, KUKA, Universal Robots, Fanuc, Yaskawa, Stäubli and Mitsubishi. If you are not sure whether your robot is compatible, please contact us.

The end effector can be changed either by hand or automatically by using a storage station and robot-controlled movement.

Thanks to its standardized interface, the MATCH robot module is compatible with most common robot models. If you are not sure about something, please contact us.