Robot-based machining machine

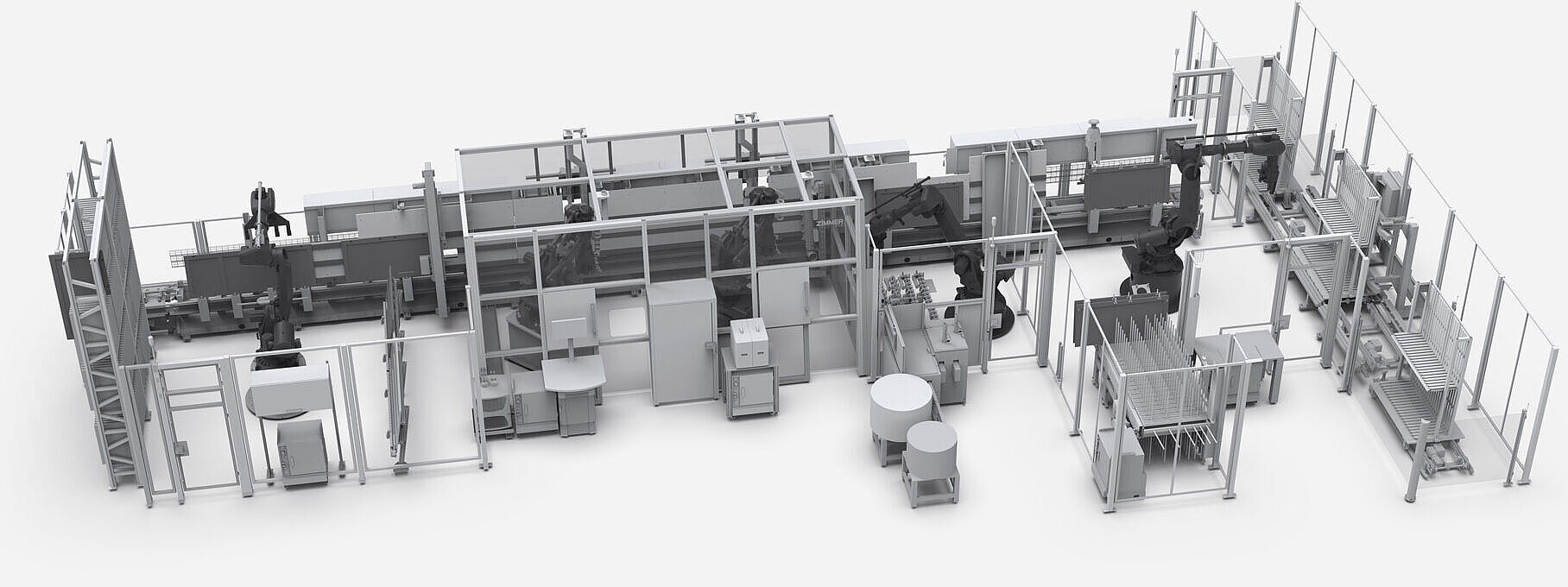

The robot-based production line enables highly flexible drilling of furniture body parts in batch size 1. An innovative shuttle carousel serves as a workpiece transport and clamping system that ensures efficient and precise machining. The automatic loading and unloading system is seamlessly connected to the customer's automated guided vehicle (AGV) systems, thereby achieving end-to-end automation.

The powerful drill head has vertical and horizontal drill spindles as well as Clamex, milling and grooving units, which enable versatile high-precision machining. In addition, metal and plastic fittings are automatically placed from pre-equipped trays. An integrated component return system also enables efficient rear-side machining of the workpieces without the need for manual intervention. Direct integration into the customer's production control system ensures seamless production control. Even with its high performance, the system requires minimal space has an impressively high availability and simple maintenance.

Highly flexible production line for machining cabinet parts in batch size 1

Robot-based machining machine

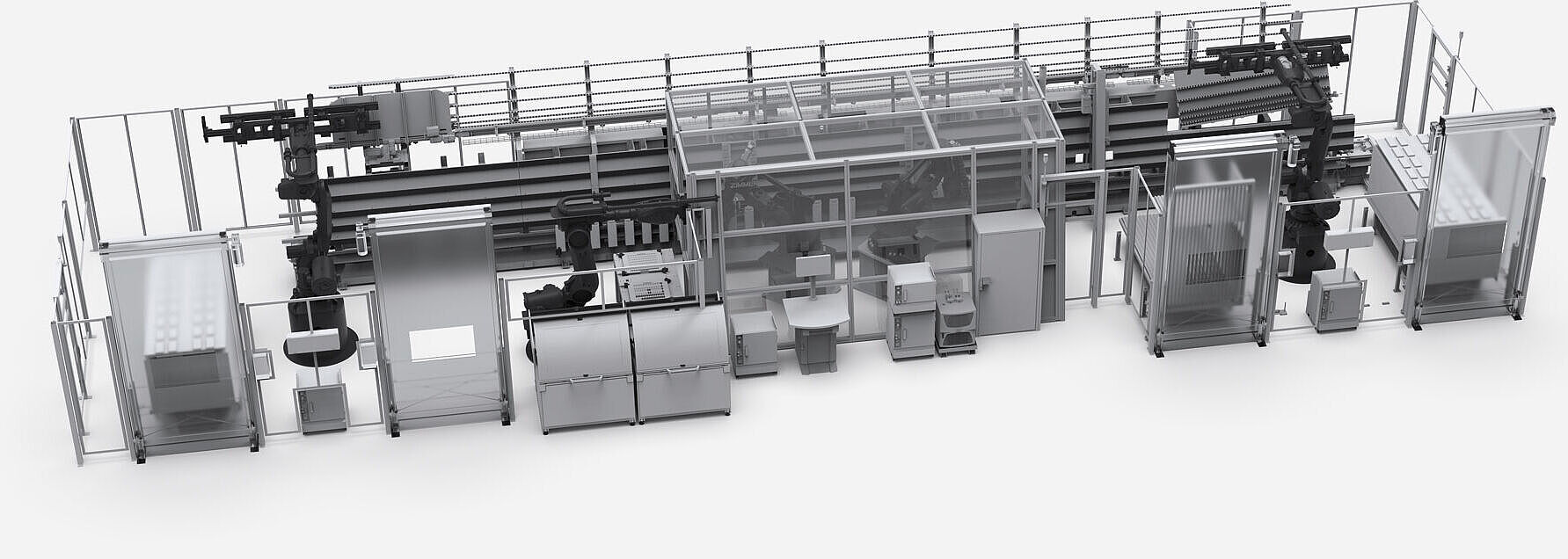

The highly flexible, innovative production line for machining furniture fronts in batch size 1 combines a highly flexible shuttle carousel as a workpiece transport and clamping system with precision-compensated industrial robots. The shuttle carousel serves as an efficient workpiece transport and clamping system and enables precise and smooth machining. Precision-compensated industrial robots take over the drilling and ensure maximum accuracy. A powerful drill head with 17 vertical spindles, a milling spindle and a buffer setting unit ensures maximum machining capacity.

There is also an integrated drill head for rear-side machining, which enables complete machining in a single process step. Fittings and hinges are set efficiently from feeder bowls and bar magazines, which supports end-to-end automation. The furniture fronts are automatically loaded and unloaded in rack trolleys, with safe storage systems guaranteeing uninterrupted trolley changes. Direct integration into the customer's production control system ensures a seamless production process.

Highly flexible production line for machining furniture fronts in batch size 1