Mobile robot

Series ZiMo1000 and ZiMo2000

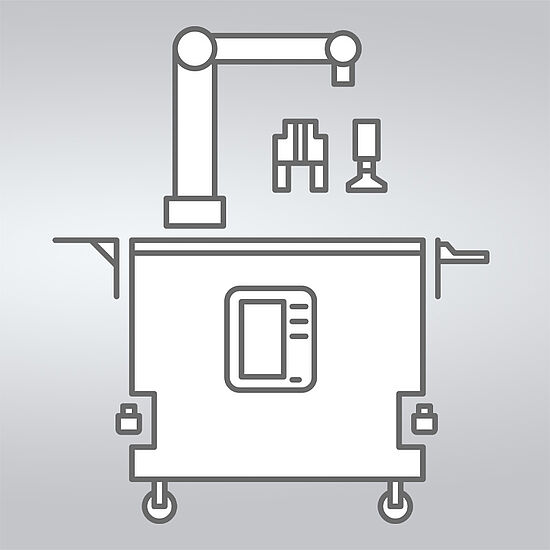

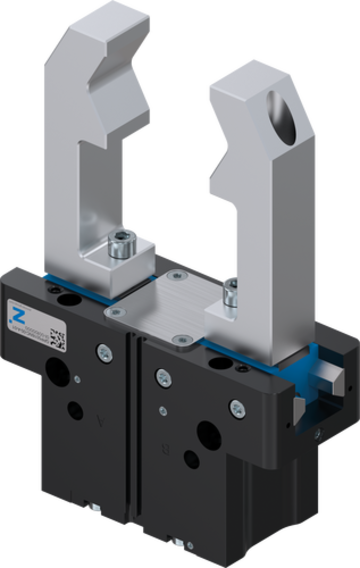

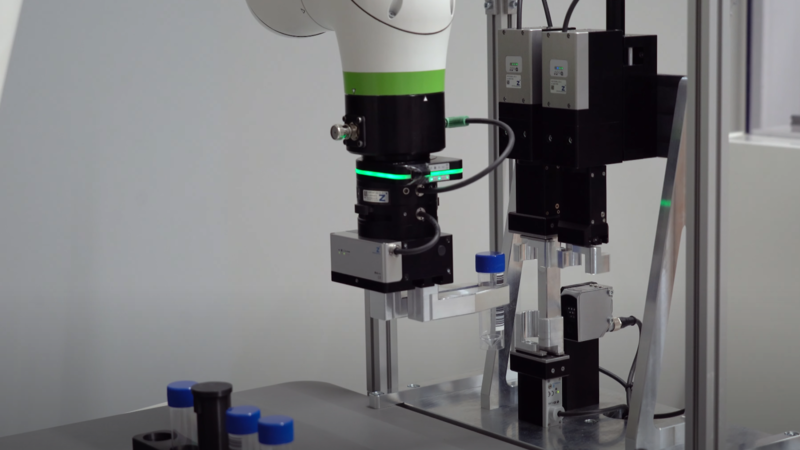

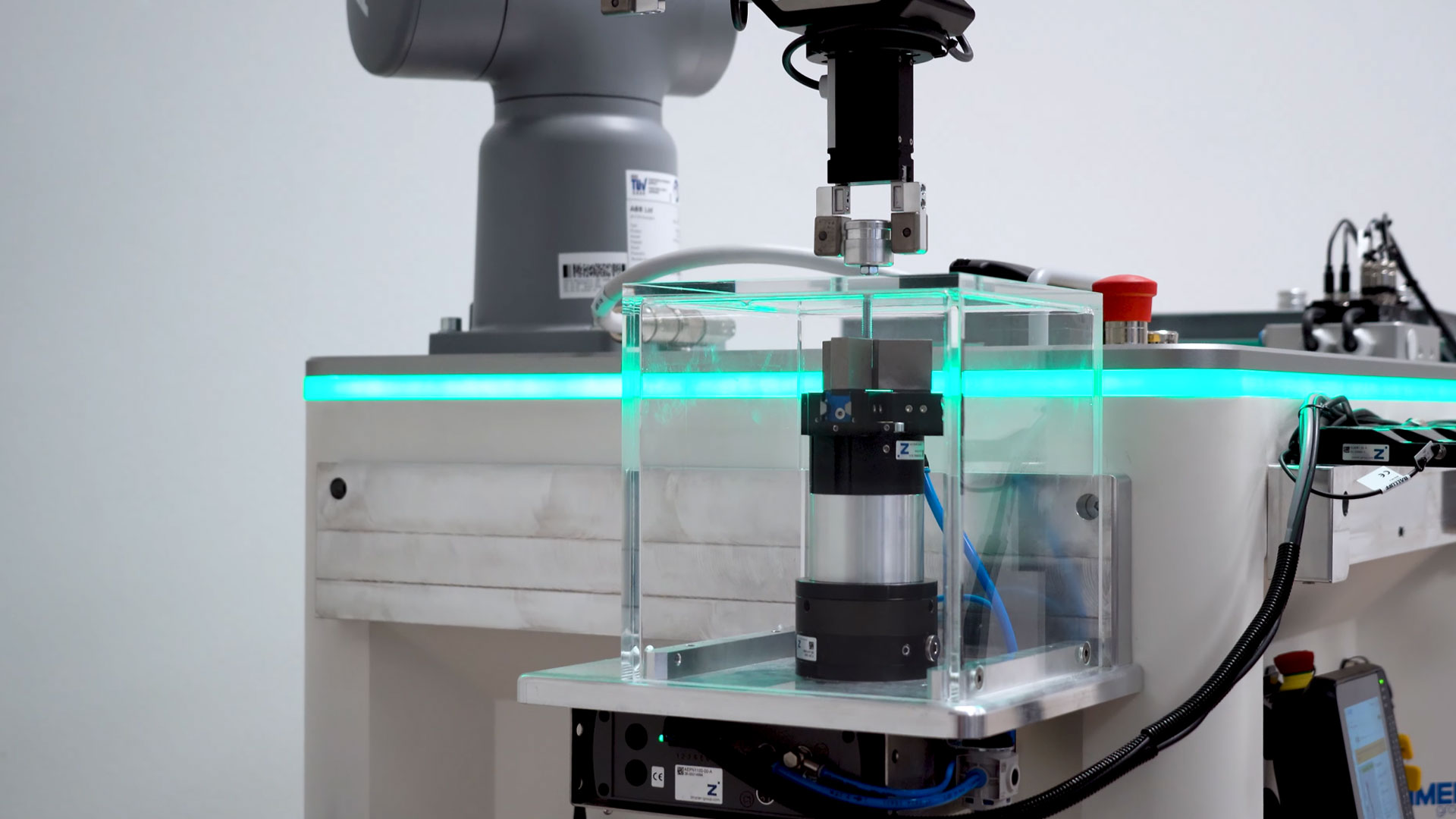

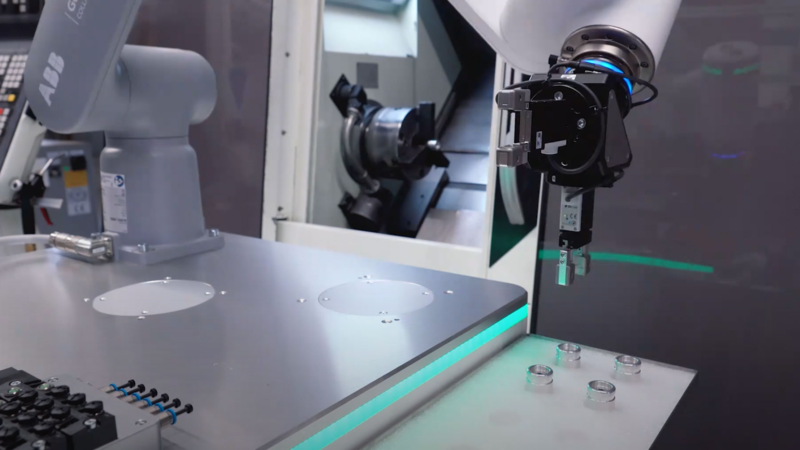

ZiMo is the Zimmer Group’s flexible and individually configurable robot cell. The compact design allows almost unrestricted positioning – exactly where you need it and adapted to your production situation. Operation is intuitive and convenient via the side-mounted control panel including a robot-neutral Human Machine Interface. The variable structure offers you maximum freedom in the choice of accessories and can be individually adapted to your needs and requirements.

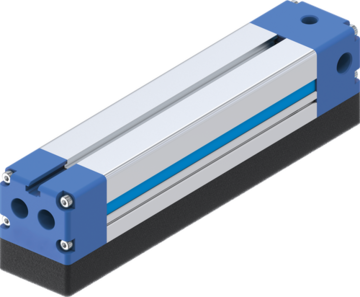

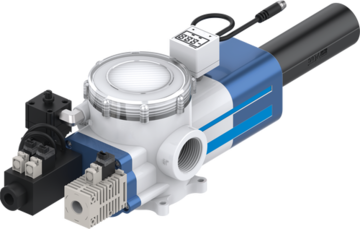

Easy Automation

(Series Zimo2000)

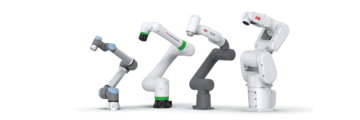

Target group – Customers with automation requirements – even without in-depth robot expertise

Focus – Simple operation

Area of use – Automation of different processes

Added value – Immediately ready for use, simple, compatible with any robot

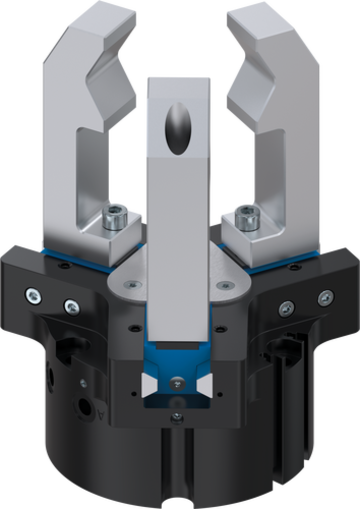

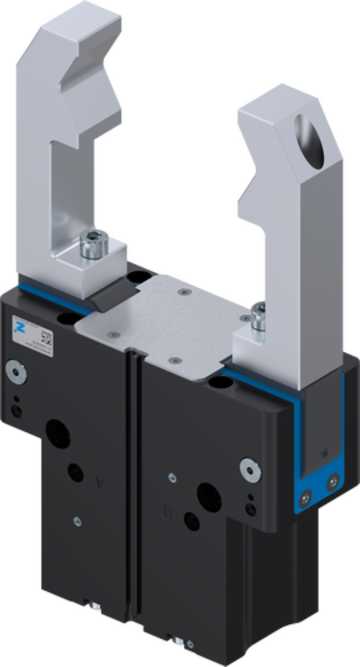

Platform Kit

(Series ZiMo1000)

Target group – System integrators, customers with robot expertise

Focus – Modularity, scalability and customizability

Area of use – Basis for independent implementation of automation for various processes

Added value – Individually configurable basis for automation solutions

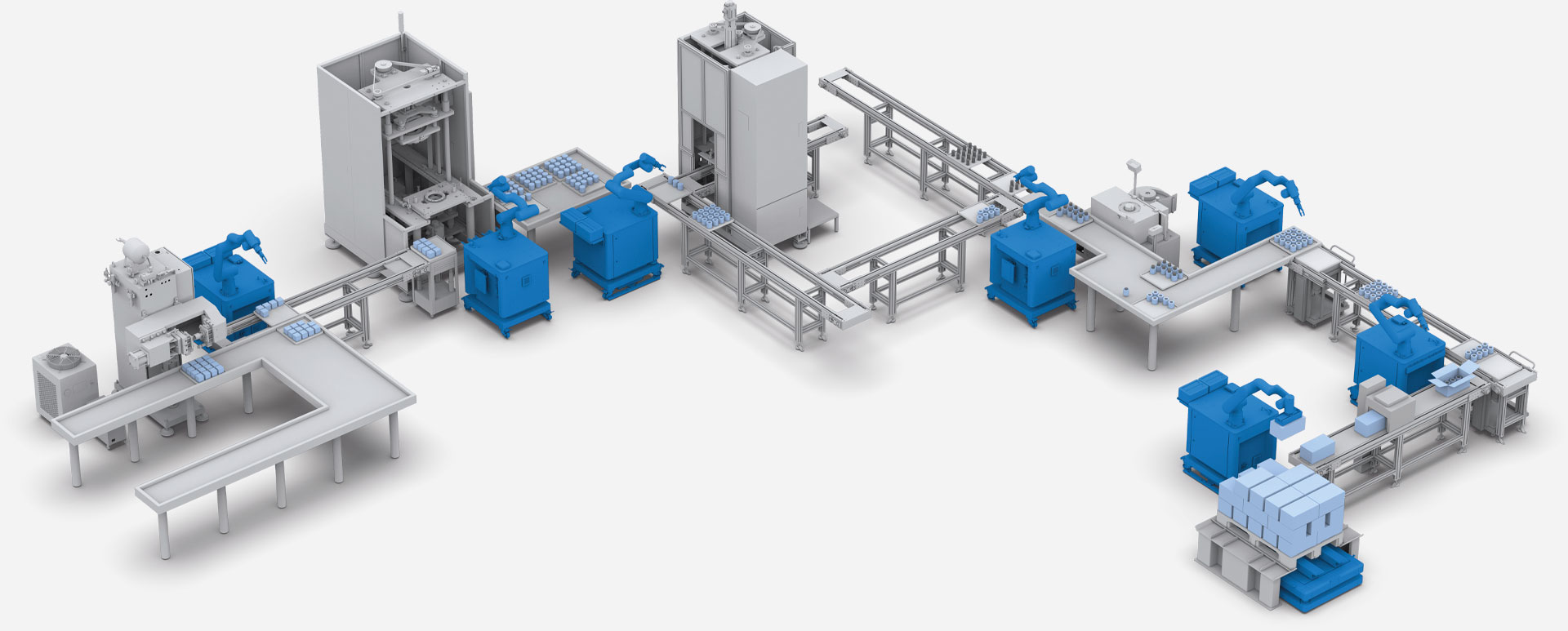

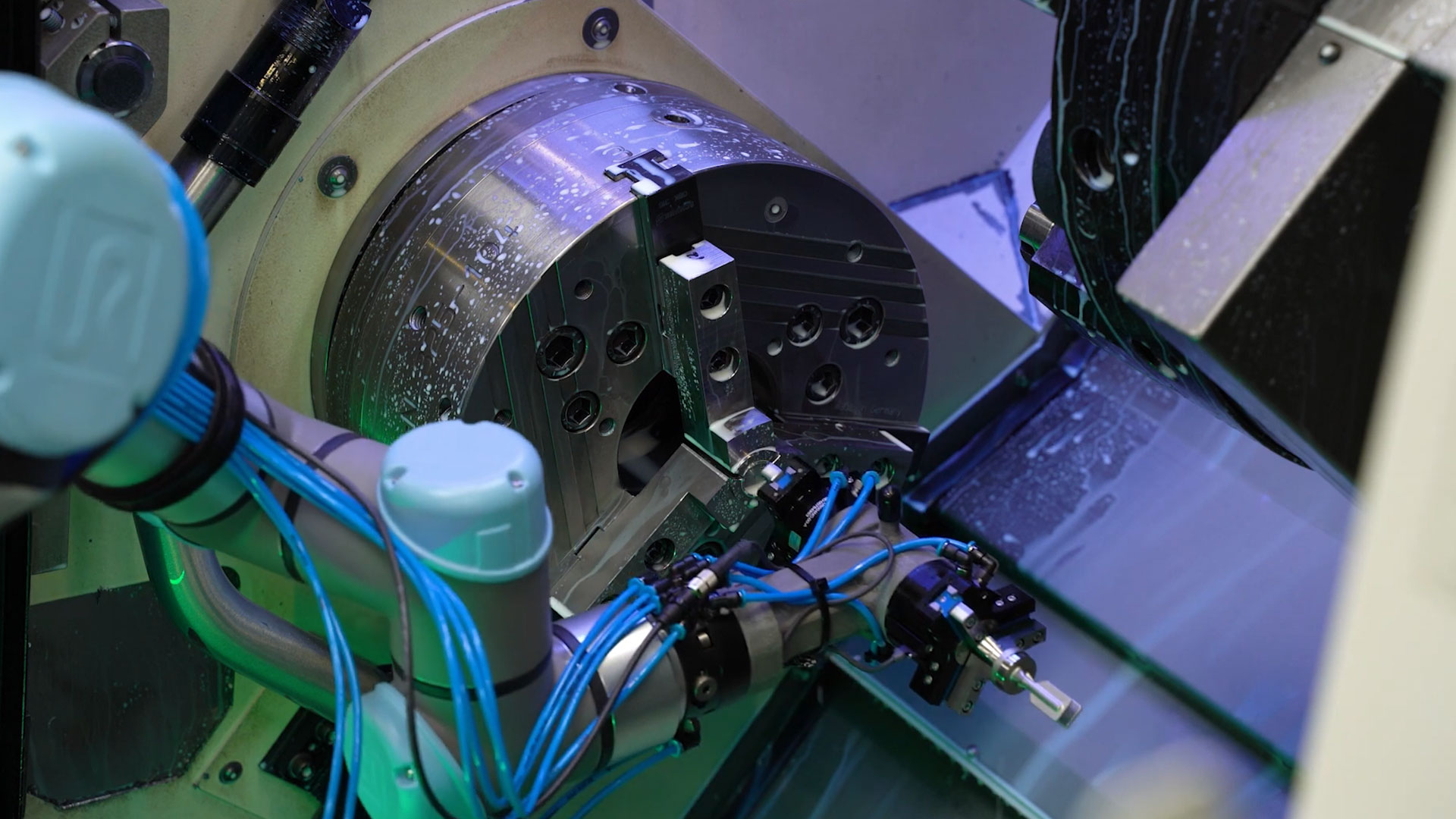

Application example