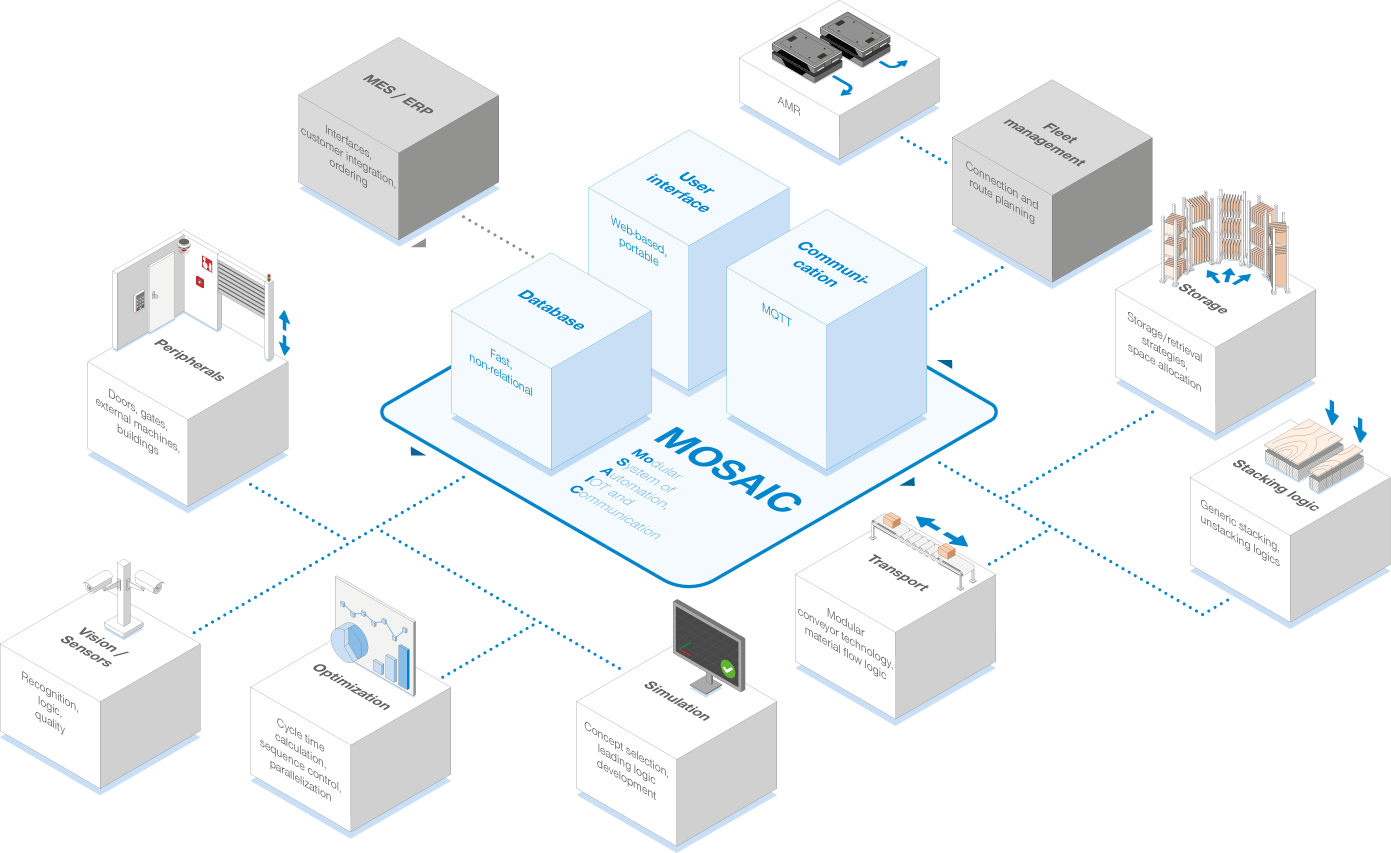

MOSAIC

The control system for all tasks – from the storage cell to the AMR

MOSAIC stands for Modular System of Automation, IOT and Communication. The software is based on an architecture consisting of many intercommunicating services and enables the management and control of simple machines up to complex systems, with more or fewer modules being used in addition to the basic system, depending on the customer concept. Flexible & scalable – we configure exactly to your requirements, all the way from simulation to delivery.

Have we piqued your interest? Then we look forward to your message!

Your benefits:

- Modular & flexible: Transport, storage, simulation, optimization & more – combined any way you like

- Seamless integration: ERP/MES, AMR, peripherals, storage technology and much more.

- Transparent data: Real-time access via high-performance database

- Intuitive operation: Web-based, device-independent interface

- Ready for Industry 4.0: Intelligent control, planning & analysis

The basic system

MOSAIC is the central control system for your production – from simple machines to complex systems. Scalable, adaptable and ready for any industrial automation challenge. MOSAIC's core provides all the functions you need to manage your system securely and from a central hub:

- User & rights management – Role-based system with fine-grained control

- Data integration & interfaces – Flexible connection to ERP-MES systems. Optionally via MQTT, Rest, OPC UA, databases (e.g. SQL) or file-based.

- HMI (human-machine interface) – Interactive control and visualization of the system

- Security – Encrypted communication across all endpoints

- Resilience – Redundant infrastructure, extremely high system availability

Periphery module

Interface to the environment of your system

The Periphery module is the digital link between your machine and its physical environment. It is responsible for the controlling, monitoring and integrating all external devices that your machine interacts with in the production environment – be it direct communication with other machines or the connection to higher-level infrastructures.

This module enables the seamless coordination of automated processes in the extended machine environment. Typical use cases include:

- Door control for automated guided vehicles (AGV): Before an AGV passes through a hall door, the Periphery module opens the door automatically and closes it after it has passed – safely, efficiently and without any person intervening.

- Reliable transfer processes between machines: An AGV transports a stack of workpieces from machine 1 to machine 2. The Periphery module coordinates the safe pick-up and delivery of the stack within the defined safety areas of the respective machines.

- Connection of safety-relevant systems: These include fire alarm systems, elevators and other building services equipment that are integrated into the process control system via defined interfaces.

Vision / Sensors module

Intelligent recognition for your production

The Vision / Sensors module integrates image processing systems into the control system via a standardized interface. It enhances the system with the ability to capture and interpret visual information and integrate it into automated processes.

Whether for quality control, positioning or measuring parts – the module ensures a reliable connection between the basic system and external vision components. Typical applications:

- Parts identification and measurement: Automatic workpiece detection, geometry inspection and position determination – precise and reliable.

- Unstacking with image control: Visual inspection of the stack image during storage or retrieval to ensure completeness and correctness.

- Standardized VISION interface: Standardized connection of a wide range of image processing systems, regardless of the manufacturer.

Integrating the Vision module not only makes your production line more intelligent, but also significantly more robust against errors – for reliable and automated quality inspections in real time.

Optimization module

Intelligent sequence planning and analysis for maximum efficiency

The Optimization module is the control center for high-performance, adaptive production control. It combines advanced planning algorithms with comprehensive analysis functions – from cycle-accurate sequence control with exact cycle timing to the data-based further development of your system.

At the heart of the module is a flexible machining job planner that optimally schedules machining jobs, taking into account the current system resources and machine configuration. One example is the drilling optimizer, which creates drilling programs from customer-specific machining data, forms drilling groups, optimizes shuttle cycles and, if necessary, intelligently distributes the machining to multiple robots.

The module also offers:

- Cycle time calculation based on real process parameters

- Dynamic sequence control with adaptation to system states

- Parallelization of processesto avoid downtimes and make better use of resources

The integrated evaluation module also provides valuable insights into the performance of your system:

- Analysis of cycle performance per sorting or machining cell: Where do bottlenecks occur, and where is there free capacity?

- Downtime analyses according to cause: Detailed transparency for improvement measures where it counts

Simulation module

Reliable planning, efficient implementation

The Simulation module specifically supports the system design and concept selection. The aim is to identify the best concept for the customer at an early stage of the project – both technically and economically.

Simulation-based modeling of material flows, cycle times and process sequences makes it possible to compare, evaluate and optimize different scenarios – even before real system components are used.

Application areas:

- Concept selection: Virtual mapping and evaluation of different system layouts and process strategies

- Commissioning support: Early validation of control and process logic in order to shorten real commissioning

- Strategy optimization: Analysis and fine-tuning of control and logistics strategies based on realistic process models

Storage module

Intelligent storage management and dynamic sorting strategies

The Storage module is the heart of the storage and sorting logic within the control system. It manages storage locations, controls storage and retrieval processes and enables dynamic adaptation to changing production requirements.

Storage management is based on flexible space allocation, including the definition of permitted part dimensions for each storage location or group of spaces. Spaces can be blocked or released specifically as needed– manually or automatically.

The integrated strategy logic supports a wide variety of storage and retrieval concepts, which can also be combined or dynamically adapted as required. The result is an efficient, adaptable storage system that can react optimally to changing workload situations.

Examples of strategies:

- Storage according to retrieval sequence: Parts are stored in such a way that a later defined sequence can be held when they are retrieved.

- Load-distributed storage: Even distribution of parts to multiple sorting cells to smooth out load peaks – even regardless of the later sequence.

- Grouped storage according to dimensions: Smaller parts can be stored together to use the storage capacities efficiently.

- Performance-optimized retrieval: If multiple cells have the same references, the one that enables the highest process performance is selected.

The Storage module gives you a combination of structured management with an intelligent, adaptable logic – for a powerful, scalable sorting and storage system.

Transport module

Intelligent control of the material flow

The Transport module maps the central logic for the material flow within the system. It controls, coordinates and optimizes the movements of the workpieces across the various conveyor sections – always in direct communication with the overall system MOSAIC.

Each conveyor is managed as an independent service in the control system. The Transport module takes over the central coordination of these services and ensures that material flows are managed efficiently, safely and flexibly.

Overview of features:

- Dynamic decision logic on the transport route: At critical transfer points – such as angled transfer units or junctions – the module makes decisions based on the particular situation, the current system status and communication with MOSAIC.

- Prioritization of parts: Workpieces are prioritized for transport according to defined criteria – such as the production sequence, availability of downstream processes or malfunctions.

- Service-based control: Each sponsor is managed by its own microservice in MOSAIC. The Transport module ensures their overall coordination and sequence control.

Stacking Logic module

Intelligent, safe and flexible stacking

The Stacking Logic module dynamically forms part stacks based on the rules of the production or logistics process. It manages the basic stacking rules and enables chaotic stacking according to definable specifications, which can be adapted to the material, order or process situation.

A special highlight: The stacking can also be used as a stand-alone system that operates independently of a connected production line and is fully integrated into existing MES/ERP landscapes.

Overview of features:

- Stable stacks due to dynamic structural analysis: Safe stacking thanks to continuous assessment of the stacking stability – even for mixed materials.

- Flexible stacking strategies: Rules can be adapted to match the particular production requirement, material type or logistical objective.

- Batch separation: Clear allocation of workpieces by batch or commission – even for mixed production orders.

- Wide range of materials covered: Whether coated panels, solid wood or components with protective film – the system automatically recognizes material-dependent requirements.

- Intelligent part detection: The logic decides which parts can be stacked together – without manual intervention.

- Live visualization of the target stacks: The current stack structure is visualized transparently – for operators, monitoring and quality assurance.

- Stand-alone or integrated use: As a stand-alone module with MES/ERP connection or integrated into the overall MOSAIC control system.

AMR & fleet management

For smart production logistics with automated guided vehicles:

- Link between production and building infrastructure and fleet management

- Interface and processing function between customer MES / ERP and the vehicle level (fleet management)

- Manages of vehicle superstructures and closes the communication gap between the machine level and vehicles

Technologies:

► mongoDB

► MQTT

► docker

► Ubuntu

► Rest API

► Angular

► GitLab

► .NET Framework

► three.js